Will wax remover additive cause environmental pollution?

2024-05-17 15:30

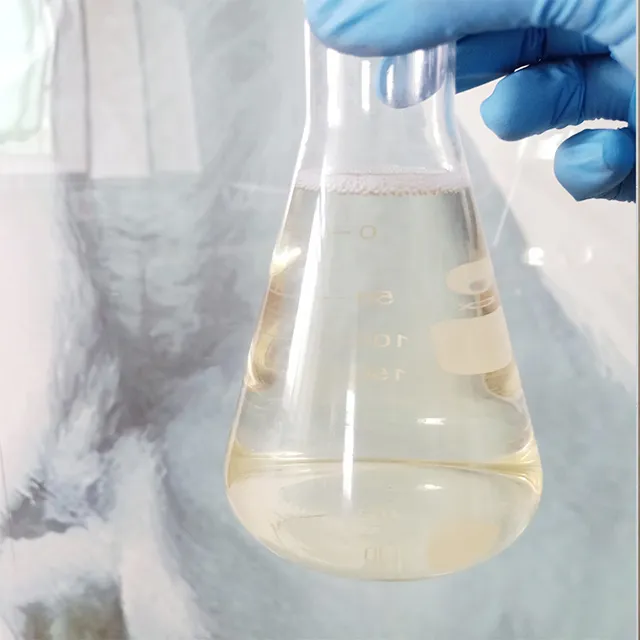

In the production and processing of aluminum products, wax remover additive is a common material used to remove residual wax and impurities from the surface. However, as environmental awareness increases, consumers and industries are increasingly concerned about the impact of wax remover additive on the environment. This news will deeply explore the potential impact of wax remover additive on the environment, analyze the pollution problems it may cause, and how to reduce adverse effects on the environment in practical applications.

1. Ingredients of wax remover additive

Wax remover additive usually consists of solvents, surfactants and other chemical ingredients. These ingredients work in the wax removal process. However, different additive formulations may have different impacts on the environment. Therefore, choosing the right additive formulation is critical to reducing contamination.

2. Waste liquid treatment issues

De-waxing Additive will produce waste liquid during use. These waste streams may contain wax, metal particles and other impurities. If the waste liquid is not treated properly, it may cause contamination of water sources and soil. Therefore, the industry should develop waste liquid treatment measures to ensure that waste liquid is properly treated.

3. Volatile organic compound (VOC) emissions

Some De-waxing Additives may contain volatile organic compounds (VOCs), which will evaporate into the atmosphere during use and affect air quality. The industry should choose low-VOC or no-VOC additives to reduce air pollution.

4. Environmental regulations and standards

Countries have relevant environmental regulations and standards for the use and discharge of De-waxing Additive. These regulations are intended to ensure that the use of additives does not adversely affect the environment. Consumers and industry should ensure that the de-waxing additive they choose complies with these regulations and standards.

5. Choose environmentally friendly wax remover additive

Modern wax remover additive manufacturers are working hard to develop more environmentally friendly products, such as biodegradable ingredients and low-toxicity formulations. These products have less impact on the environment during use and should be given priority by consumers and industries when choosing.

6. Sustainable production

The industry should reduce the environmental impact of wax remover additive through sustainable production methods. This includes optimizing production processes, reducing the use of additives and improving waste treatment technology to achieve sustainable use of resources.

7. Training and education

Workers have an important influence on the correct use and handling of wax remover additive. Through training and education, workers can better master the use skills of wax remover additive and waste liquid treatment methods, reducing potential pollution to the environment.

8. Scientific research and technological innovation

Scientific research and technological innovation play an important role in reducing the environmental impact of wax remover additive. New additive formulations, new waste liquid treatment technologies, and the application of new environmentally friendly materials can all help reduce adverse impacts on the environment.

9. Consumer choice

When consumers choose aluminum products, they can pay attention to whether environmentally friendly wax remover additive is used in the production process. This choice helps push the industry in a greener direction.

De-waxing Additive plays an important role in the production of aluminum products, but its potential impact on the environment also requires attention. By choosing environmentally friendly additives, improving waste treatment measures, strengthening training and education, and scientific research and innovation, the industry can reduce its negative impact on the environment and achieve more sustainable development. Consumers and industry should work together to contribute to environmental protection.