How good is the anti-fouling ability of wax remover additive on aluminum products?

2024-05-16 15:30

Effect of wax remover additive on anti-fouling ability of aluminum products

Aluminum products are widely used in modern industry and life, from auto parts to home appliance casings to building materials, all of which are inseparable from the participation of aluminum products. However, aluminum products often encounter various surface treatment problems during the production process, such as surface oxidation, dirt adhesion, etc. As a commonly used surface treatment material, wax remover additive plays an important role in the anti-fouling ability of aluminum products. This article will explore the effect of wax remover additive on the anti-fouling ability of aluminum products, as well as its value in production and application.

1. How wax remover additive works

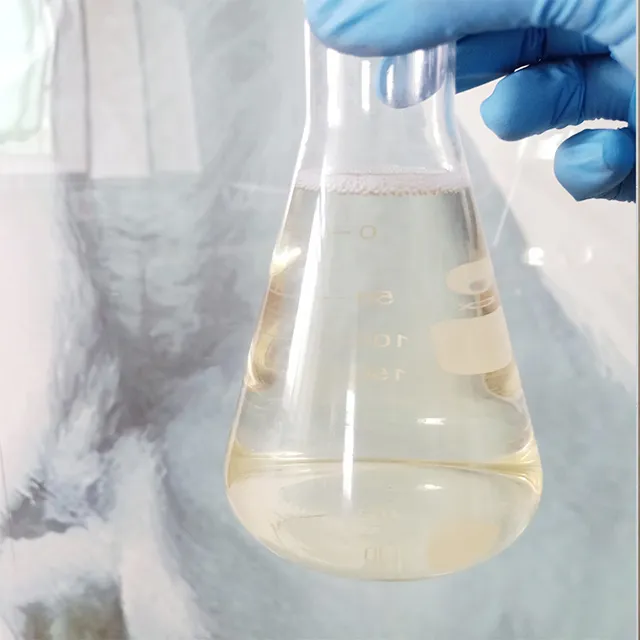

Wax remover additive is mainly used to remove wax and other organic matter produced on the surface of aluminum products during the production process. These waxes may originate from mold processing, surface protection and other aspects. If not removed in time, it will cause the surface of the aluminum product to be uneven and not smooth, and even affect subsequent processes. Wax remover additive dissolves wax on the surface through a chemical reaction, keeping aluminum products clean and smooth.

2. Improve the anti-fouling ability of aluminum products

De-waxing Additive can not only remove wax from the surface, but also enhance the stain resistance of aluminum products. By removing surface residue and impurities, aluminum surfaces are easier to keep clean and less likely to absorb dirt. Especially in aluminum products for outdoor use, good stain resistance can help extend the service life of the product and reduce cleaning and maintenance costs.

3. Protect surface oxide layer

The use of De-waxing Additive helps protect the surface oxide layer of aluminum products. The surface oxide layer is an important barrier for aluminum products to resist corrosion and stains. By removing wax and impurities, De-waxing Additive ensures the integrity and uniformity of the oxide layer, thereby improving the durability and stain resistance of aluminum products.

4. Improve coating adhesion

During the coating process of aluminum products, wax remover additive can improve the adhesion between the coating and the aluminum surface. The cleaned surface bonds more easily to the coating, forming a strong protective layer. This helps prevent dirt from penetrating into the aluminum product and improves its anti-fouling properties.

5. Improve process efficiency

The use of wax remover additive can improve the efficiency of the production process. By quickly removing wax and impurities, aluminum products are processed faster on the production line, reducing wait times in the process. This not only improves production efficiency, but also reduces production costs.

6. Impact on the environment and worker health

High-quality de-waxing additives are generally environmentally friendly and safe, with less impact on the environment and workers' health. However, consumers and industries should ensure that the de-waxing additives they choose comply with environmental regulations to avoid unnecessary harm to the environment and workers.

7. Combination with other surface treatment processes

Wax remover additive can be combined with other surface treatment processes, such as polishing, anodizing, etc. This combination can further improve the anti-fouling ability of aluminum products, making them perform better in various application scenarios.

8. Choose the right wax remover additive

Choosing the right De-waxing Additive is crucial to the stain resistance of aluminum products. Consumers and industries should choose the appropriate de-waxing additive based on the application scenarios and surface treatment requirements of aluminum products to ensure the best anti-fouling effect.

Wax remover additive plays an important role in the ability of aluminum products to resist stains. By removing wax and impurities from the surface, wax remover additive improves the anti-fouling performance of aluminum products, protects the surface oxide layer, and improves coating adhesion. Consumers and industries should choose the appropriate wax remover additive based on specific needs to ensure that aluminum products perform well in production and applications.