How to tell if aluminum is anodized? Why anodize aluminum?

2024-07-09 15:30

Anodizing is an electrochemical treatment method widely used on the surface of aluminum and aluminum alloy materials. It significantly improves its performance and appearance by forming a protective oxide film on the aluminum surface.

So, how to tell if aluminum is anodized? Why is aluminum anodized? This article will explore these issues in detail to help readers gain a deeper understanding of the applications and benefits of the anodizing process.

How to tell if aluminum is anodized?

Methods to judge whether aluminum has been anodized: appearance observation (uniform and delicate appearance), surface hardness (higher hardness, strong wear resistance), strong corrosion resistance, conductivity test (low conductivity), microscope observation (surface form a porous structure). The specific judgment is as follows:

1. Appearance observation:

Anodized aluminum surfaces typically have a uniform, fine appearance. Through naked eye inspection, you can see that the surface has a matte or semi-glossy texture, while untreated aluminum may exhibit a rougher surface.

●Color: Anodized aluminum can be dyed, with various and uniform colors. Untreated aluminum is usually silvery white or slightly metallic.

●Glossiness: The surface gloss of the anodized aluminum material is high and has a metallic luster. Untreated aluminum, on the other hand, may be dull.

2. Surface hardness:

The surface hardness of the anodized aluminum material is significantly improved, which can be judged by hardness testing. Use a hardness tester to test. The surface hardness of anodized aluminum is usually higher and the wear resistance is enhanced.

3. Corrosion resistance:

The corrosion resistance of aluminum materials after anodization is significantly improved, which can be judged through corrosion tests. Soak aluminum in an acidic or alkaline solution and observe changes in its surface. The surface of anodized aluminum has strong corrosion resistance and small changes, while untreated aluminum may corrode.

4. Conductivity test:

An insulating oxide film is formed on the surface of the anodized aluminum material, which can be judged by conductivity testing. Using a conductivity meter for testing, the surface conductivity of anodized aluminum is low, while the conductivity of untreated aluminum is high.

5. Microscope observation:

By observing the surface structure of the aluminum material through a microscope, you can determine whether it has been anodized. The surface of anodized aluminum forms a porous structure, while the surface of untreated aluminum is relatively smooth.

Why is aluminum anodized?

The main reasons for anodizing aluminum are: to improve corrosion resistance, enhance wear resistance, improve decorative appearance, improve adhesion, insulation performance, and improve heat resistance.

1. Improve corrosion resistance:

Aluminum materials are prone to oxidative corrosion in the natural environment. Although the generated aluminum oxide film has a certain protective effect, the film is thin and the protective effect is limited. Through anodizing, a dense and thick aluminum oxide film can be formed on the surface of the aluminum material, which greatly improves its corrosion resistance and extends its service life.

2. Enhance wear resistance:

The surface hardness of the anodized aluminum material is significantly improved, enhancing its wear resistance. Especially in application scenarios where friction and wear are serious, such as mechanical parts and auto parts, anodizing can effectively reduce wear and keep the surface smooth.

3. Improve the decorative appearance:

Anodized aluminum can be dyed in a variety of colors to meet different decorative needs. Through anodizing, the aluminum surface can show beautiful colors and textures, and it is widely used in architectural decoration, electronic product casings and other fields. For example, Apple's iPhone and MacBook cases are anodized to give them rich colors and an elegant appearance.

4. Improve adhesion:

The porous structure formed on the surface of anodized aluminum facilitates the adhesion of coatings or adhesives. Through anodizing treatment, the bonding force between the aluminum material and the coating or adhesive can be improved, enhancing its adhesion and ensuring that the coating is not easy to fall off.

5. Insulation performance:

The oxide film on the surface of anodized aluminum has good insulation properties. In the electronics and electrical fields, anodized aluminum can be used as an insulating material to prevent current leakage and ensure the safety and reliability of electronic equipment.

6. Improve heat resistance:

The oxide film on the surface of anodized aluminum has high heat resistance and can withstand higher temperatures without changing. Especially for aluminum materials used in high-temperature environments, anodizing can improve their heat resistance and ensure their stability and safety.

Application examples of anodizing

Anodizing is widely used in various fields. For example: architectural decoration (curtain walls, window frames, door frames), electronic products (mobile phones, laptops), automotive industry (body, wheels), aerospace (aircraft structural parts and components), household products (kitchenware, furniture).

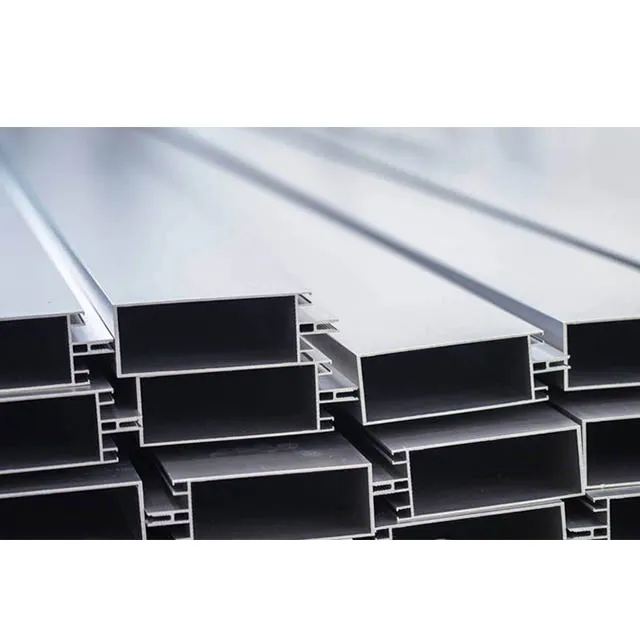

1. Architectural decoration:

In the field of architectural decoration, anodized aluminum is widely used in curtain walls, window frames, door frames, etc. Through anodizing, the aluminum surface can show rich colors and textures to meet different architectural design needs. For example, the facades of many modern buildings are made of anodized aluminum, which is not only beautiful and elegant, but also has excellent weather resistance and corrosion resistance.

2. Electronic products:

In the field of electronic products, anodized aluminum is widely used in the casings of mobile phones, laptops, tablets and other products. The anodizing process not only gives electronic products diverse colors and elegant appearance, but also improves their wear resistance and fingerprint resistance. For example, Apple's iPhone and MacBook cases use an anodizing process to make them look beautiful and feel comfortable.

3. Automobile industry:

In the automotive industry, anodized aluminum is widely used in body parts, wheels, roof racks and other components. Through anodizing treatment, the corrosion resistance and wear resistance of aluminum materials can be improved and the service life can be extended. For example, the aluminum alloy wheels of many high-end cars are anodized, which is both beautiful and durable.

4. Aerospace:

In the aerospace field, anodized aluminum is widely used in aircraft structural parts and components. Anodizing treatment can improve the corrosion resistance and wear resistance of aluminum materials, ensuring its stability and safety in harsh environments. For example, anodized aluminum is often used in aircraft wings, fuselages and engine components to improve their durability and reliability.

5. Household items:

In the field of household products, anodized aluminum is widely used in kitchenware, furniture, lighting fixtures, etc. Through anodizing treatment, the aluminum surface can show beautiful colors and textures, improving its decorativeness and practicality. For example, many high-end kitchenware and furniture are made from anodized aluminum, which is both beautiful and durable.

Conclusion

Aluminum anodizing is an important surface treatment process that significantly improves the performance and appearance of aluminum by creating a protective oxide film on its surface.

Determining whether aluminum has been anodized can be carried out through appearance observation, surface hardness test, corrosion resistance test, conductivity test and microscope observation. Anodizing aluminum has many advantages including improved corrosion resistance, enhanced wear resistance, improved cosmetic appearance, improved adhesion, providing insulating properties and improved heat resistance.