How do electrolytic coloring additives change the color of aluminum?

2024-07-22 15:30

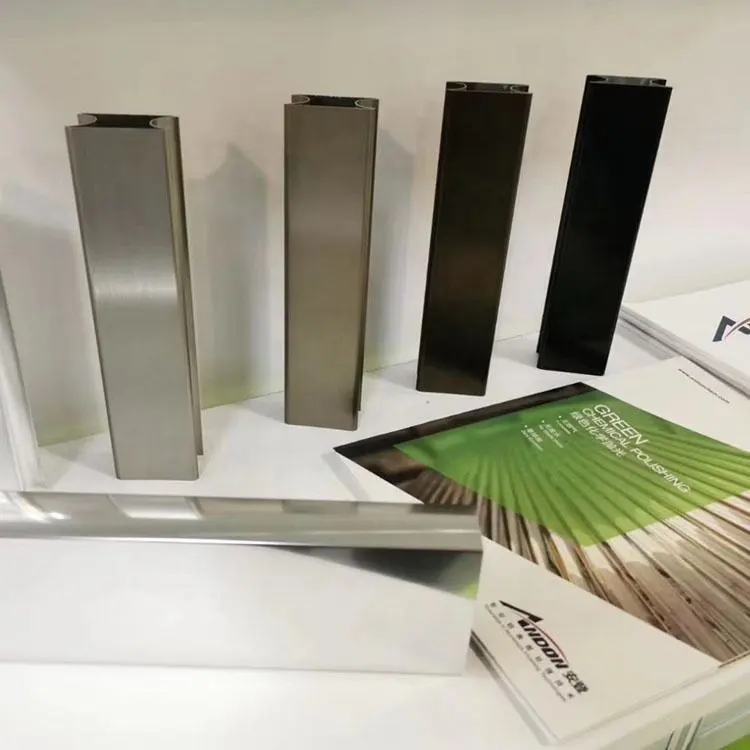

The dull color of pure aluminum limits its potential in decorative applications. Through the electrolytic coloring process, the color of aluminum can be significantly changed, giving it higher decorative value and functionality.

This article takes an in-depth look at how electrolytic coloring additives change the color of aluminum, revealing the science behind the process and how it performs in practical applications.

What is the basic principle of electrolytic coloring?

Electrolytic coloring is a process that uses electrochemical reactions to form an oxide film on the surface of aluminum and its alloys and color it. The process is usually divided into two steps: first, a dense aluminum oxide film is formed on the aluminum surface through anodization; then, specific coloring additives are added to the electrolyte, and the additives are embedded into the oxide film through current to achieve color. changes.

How do electrolytic coloring additives change the color of aluminum?

Electrolytic coloring additives play a key role in changing the color of aluminum. According to different chemical compositions, additives can be divided into metal salts, organic dyes and inorganic pigments. Each type of additive has a unique mechanism of action in the electrolytic coloring process.

1. Metal salt additives

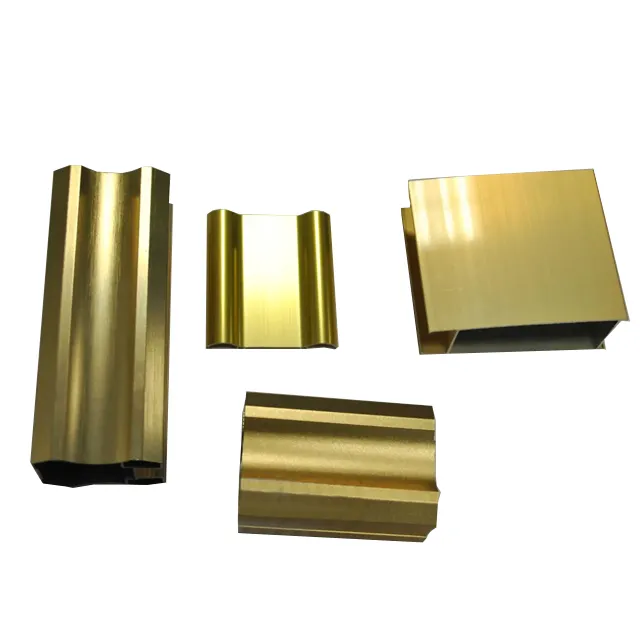

Metal salt additives, such as titanates, tungstates and manganates, produce colored metal oxides or hydroxides through electrochemical reactions. These compounds form a uniform distribution in the oxide film and exhibit a specific color. For example, titanate additives can produce yellow or gold oxides, while manganate additives can produce black or dark brown oxides.

2. Organic dye additives

Organic dye additives are embedded in the oxide film through adsorption or chemical bonding. This type of additive has the characteristics of bright colors and rich types, and can achieve a variety of coloring effects. For example, azo dyes and phthalocyanine dyes are available in various shades of red, blue, green, and more.

3. Inorganic pigment additives

Inorganic pigment additives generate colored pigment particles through physical embedding or chemical reaction, and these particles form a stable color layer in the oxide film. Iron oxide and titanium oxide, for example, create red and yellow pigment particles that give aluminum surfaces long-lasting color effects.

The specific process of electrolytic coloring process

The electrolytic coloring process includes four main steps: surface pretreatment, anodization, coloring treatment and post-treatment. Here's a detailed look at each step:

1. Surface pretreatment

Surface pretreatment is an important link to ensure the effect of electrolytic coloring. First, use an alkaline or acidic solution to clean the aluminum surface to remove oil and scale. Then, mechanical polishing or chemical polishing is used to make the surface smooth and smooth, which is convenient for subsequent anodizing and coloring treatments.

2. Anodizing

The pretreated aluminum is immersed in an electrolyte containing sulfuric acid or oxalic acid, and direct current is applied to form a dense aluminum oxide film on the aluminum surface. The time and current density of anodization determine the thickness and pore structure of the oxide film, which have an important impact on the subsequent coloring effect.

3. Coloring

On the basis of the oxide film formed by anodization, aluminum is immersed in an electrolyte containing specific additives, and current is applied to cause the additives to enter the oxide film through electrochemical reaction or physical embedding, forming a uniform color layer. Parameters such as coloring time, current density and additive concentration need to be strictly controlled to ensure color uniformity and stability.

4. Post-processing

After the coloring treatment, the aluminum surface needs to be sealed, usually using hot water or steam, to shrink the pores of the oxide film and further enhance corrosion resistance and color stability. Finally, cleaning and drying are performed to obtain the final colored aluminum product.

Advantages of Electrolytic coloring additives

1. Rich colors and good decorative effect

Electrolytic coloring additives can achieve a variety of colors and meet the decorative requirements of aluminum products in different fields. In particular, organic dye additives can provide a wide range of color choices and enhance the aesthetics of products by formulating different dye combinations.

2. Enhance corrosion resistance and wear resistance

The oxide film formed by the electrolytic coloring process has high density and uniformity, which significantly improves the corrosion resistance of aluminum. At the same time, certain ingredients in the additives, such as metal salts and inorganic pigments, can further enhance the hardness and wear resistance of the oxide film.

3. Environmentally friendly

Modern Electrolytic coloring additives usually use non-toxic and harmless ingredients, reducing environmental pollution. In particular, some new organic dye additives have good biodegradability and are more environmentally friendly.