How to use acid etching additive correctly for best results?

2024-02-27 15:35

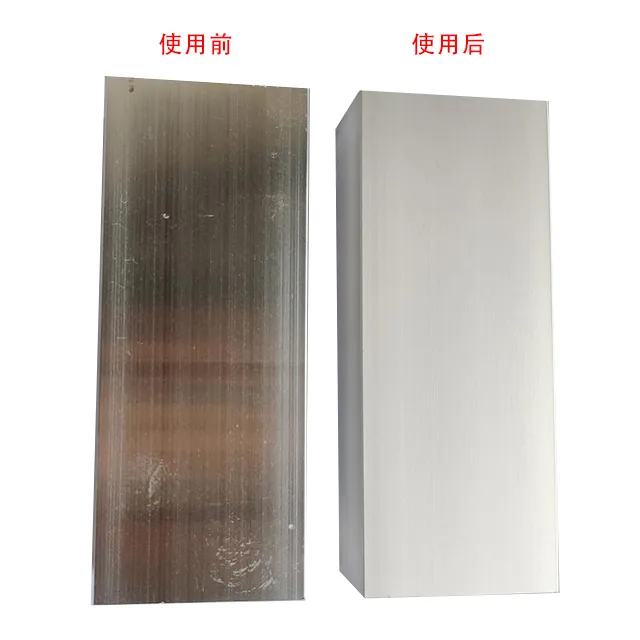

As a commonly used surface treatment agent, acid etching additive is widely used in the production and processing of various metal products. However, to get the best treatment results, correct application is crucial. Today, we’ll dive into how to properly use acid etching additive to get the best results.

1. Select the appropriate acid corrosion additive: customized as needed

Different types of metals and different processing needs may require different types of acid etching additives. Therefore, when choosing acid etching additive, you should carefully consider and select according to the actual situation. Some common acid corrosion additives include hydrochloric acid, nitric acid, phosphoric acid, etc., each of which has its applicable scenarios and characteristics.

2. Determine appropriate concentration and temperature: strictly control processing conditions

The concentration of acid etching additive and treatment temperature are important factors affecting the treatment effect. Concentrations and temperatures that are too low may not achieve the desired treatment results, while those that are too high may cause excessive corrosion or other problems. Therefore, when using acid corrosion additive, the processing conditions should be strictly controlled to ensure that the concentration and temperature are within the appropriate range.

3. Control processing time: avoid over-processing

The length of treatment time directly affects the quality of the acid etching effect. Treatment times that are too short may not completely remove oxides and impurities from the surface, while treatment times that are too long may result in excessive corrosion and damage. Therefore, when using acid corrosion additive, the processing time should be reasonably controlled according to the specific situation to avoid over-processing.

4. Pay attention to safety protection: take protective measures

Acid etching additive is corrosive and irritating to a certain extent. Therefore, safe operating procedures should be strictly followed and corresponding protective measures should be taken during use. This includes wearing protective glasses, gloves and protective clothing to ensure personal safety and environmental safety.

5. Make good use of neutralization and cleaning: ensure complete treatment

After the treatment is completed, the remaining acid should be neutralized and cleaned in time. This can effectively prevent further corrosion and contamination problems caused by acid residue, ensuring thorough treatment and clean surfaces.

6. Regularly maintain equipment: ensure long-term stable operation

The use of acid corrosion additive requires corresponding equipment and facilities, such as acid tanks, circulation pumps, etc. Regular maintenance of these equipment and keeping it in good working condition is crucial to ensure the stability and effect of acid etching treatment.

7. Adhere to quality control: ensure consistency and stability

Finally, to ensure that acid etching additive is used consistently, continuous quality monitoring and management is required. Through regular testing and analysis of processed samples, processing parameters and processes are adjusted in a timely manner to ensure the stability and consistency of the processing effect.

Conclusion: Precise operations help achieve the best results

In the process of correct use of acid corrosion additive, precise operation and strict control are key. Only by rationally selecting additives, strictly controlling processing conditions, paying attention to safety protection and other measures can we obtain the best processing effect and ensure product quality and process stability.