Can acid etching additive reduce production costs?

2024-02-27 15:30

In the field of industrial production, improving efficiency and reducing costs have always been the goals pursued by enterprises. As a surface treatment process, whether acid etching additive can reduce production costs has become the focus of attention in the industry. This article will delve into this issue in depth and provide companies with a clearer basis for decision-making.

1. The introduction of acid etching additive: a powerful tool to improve efficiency

First, we need to understand the actual application of acid corrosion additive in production. Acid etching additive mainly cleans the metal surface to create better conditions for subsequent processing. Whether the introduction of this process can improve production efficiency is directly related to the reduction of production costs.

2. Surface cleaning effect: reduce product defective rate

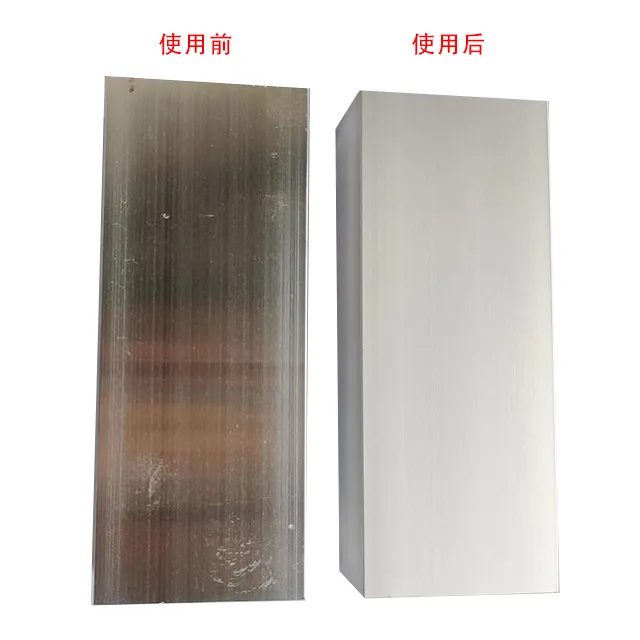

Acid etching additive makes the surface clearer by cleaning oxides and dirt from the metal surface. This not only improves the appearance quality of the product, but also reduces the defective rate of the product. Reducing the defective rate directly reduces the generation of waste products and creates good prerequisites for reducing production costs.

3. Improve equipment utilization: speed up the production process

The use of acid corrosion additive can improve equipment utilization. The rapid process of cleaning metal surfaces speeds up the production process and allows equipment to run more efficiently. Improving equipment utilization not only shortens the production cycle, but also reduces the waste of energy and other resources, providing substantial support for production cost savings.

4. Extend equipment life: reduce maintenance costs

By using acid etching additive, the process of cleaning metal surfaces can help extend the life of your equipment. It reduces corrosion and wear of equipment, reduces maintenance costs and the frequency of equipment replacement, and provides effective control over enterprise expenditures on production equipment.

5. Precise material usage control: reduce waste and cost

The use of acid etching additive can bring precise control of material dosage. The process of cleaning the surface is more precise and avoids excessive material waste. This precise control helps reduce the use of raw materials, thereby reducing production costs to a certain extent.

6. Cost-benefit analysis: comparison with traditional methods

Before introducing acid etching additive, a cost-benefit analysis is essential. Compared with traditional surface treatment methods, a comprehensive comparative analysis is carried out by comprehensively considering the use cost of acid corrosion additive, production efficiency improvement, equipment life extension and other aspects to provide scientific basis for enterprises to formulate the most economical production plan.

7. The balance between environmental protection and economy: discussion on sustainable development

In addition to cost-effectiveness, the environmental protection of acid etching additive also needs to be considered. Enterprises can explore the balance between environmental protection and economy and choose more environmentally friendly acid corrosion additive formulas, which not only reduces production costs, but also conforms to the concept of sustainable development.

8. Industry practice sharing: learn from successful experiences

Finally, companies can learn from those in the industry that have successfully used acid etching additives. By learning from advanced production practices, we can understand the problems and solutions that may be encountered in actual operations, and improve the company's control over the effectiveness and economy of using acid corrosion additive.

Conclusion

Overall, whether the use of acid corrosion additive can reduce production costs involves many factors, including production efficiency, equipment utilization, maintenance costs, material usage control, cost-benefit analysis, environmental protection balance, etc. Through scientific analysis and reference to practical experience, companies can better evaluate the actual value of acid etching additive in their production processes, laying the foundation for improving competitiveness and sustainable development.