Does acid etching additive affect the conductivity of the product?

2024-05-02 15:30

In the field of metal processing and surface treatment, acid etching additive is a commonly used chemical that is widely used to remove oxide layers on metal surfaces, clean surfaces, and improve surface quality. However, there are certain doubts and speculations about whether acid etching additive will affect the conductivity of products. Today, we will delve into this issue and reveal the impact of acid etching additive on product conductivity, bringing more understanding and enlightenment to consumers and industry practitioners.

1. Basic principles and functions of acid etching additive

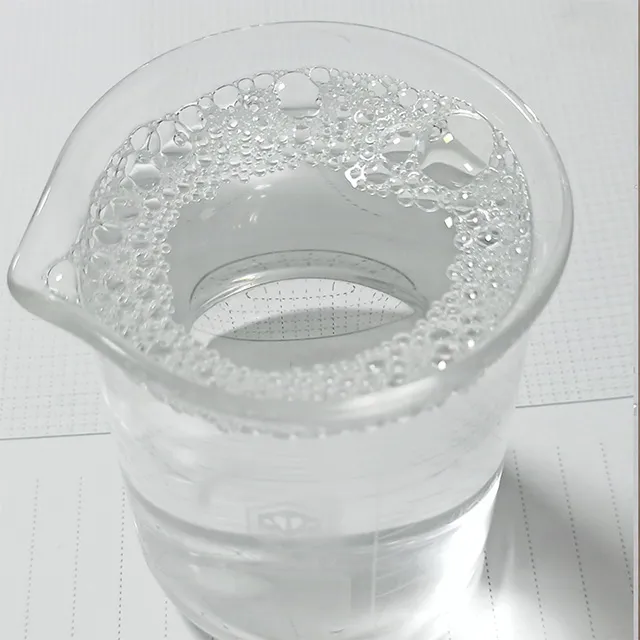

First, let us understand the basic principles and functions of acid etching additive. Acid etching additive is a chemical used for metal surface treatment. Its main ingredients usually include acidic substances, surfactants and other additives. Its function is to remove the oxide layer, dirt and impurities on the metal surface, making the surface smooth and clean, and providing a good foundation for subsequent processing and treatment.

2. Effect mechanism of acid corrosion additive on electrical conductivity

The influence mechanism of acid corrosion additive involves many aspects. First of all, in the process of removing the oxide layer on the metal surface, acid corrosion additive may change the chemical composition and structure of the surface, thereby affecting the conductive properties of the metal. Secondly, the chemical components in the acid corrosion additive may remain on the metal surface, forming a film or compound, which affects the conductivity. In addition, the pH value and concentration of the acid corrosion additive may also affect the conductivity. A pH value that is too high or too low may cause corrosion and damage to the metal surface, affecting the conductive performance.

3. Experimental verification and research results

Some experimental verification and research have been conducted on the impact of acid etching additive on product conductivity. Some studies have shown that the use of acid etching additive does have a certain impact on the conductivity of metal surfaces, especially in acidic environments and at higher concentrations, the impact is more significant. However, the specific degree and scope of the impact depends on factors such as the material of the product, the formula and usage conditions of the acid etching additive.

4. Industry response and handling suggestions

In order to reduce the impact of acid etching additive on product conductivity, some industry response and treatment recommendations need to be taken. First of all, companies should choose the appropriate acid etching additive and select the appropriate formula and concentration according to the characteristics and requirements of the product to avoid excessive corrosion and damage to the metal surface; secondly, the time and temperature of the acid etching treatment should be strictly controlled to avoid excessive processing and residue; finally, for some products that require higher electrical conductivity, other surface treatment methods, such as mechanical polishing, electrochemical polishing, etc., can be used to maintain their good electrical conductivity.

5. Future prospects and research directions

In the future, we need to further study the impact mechanism of acid corrosion additive on product conductivity and explore more scientific and effective treatment methods. At the same time, the industry should strengthen the supervision and management of acid corrosion additives and formulate relevant standards and specifications to ensure product quality and safety. We believe that through our joint efforts, we can better cope with and solve this problem and make greater contributions to the sustainable development of the industry.