Is acid etching additive suitable for large-scale production?

2024-05-01 15:30

With the continuous advancement of industrialization, the metal processing industry has an increasing demand for surface treatment technology. Among them, acid corrosion additive, as a key material for surface treatment, has attracted much attention for its applicability in mass production. This article will discuss the applicability of acid etching additive in large-scale production and answer common questions that consumers and industries are concerned about.

1. Characteristics of acid etching additive

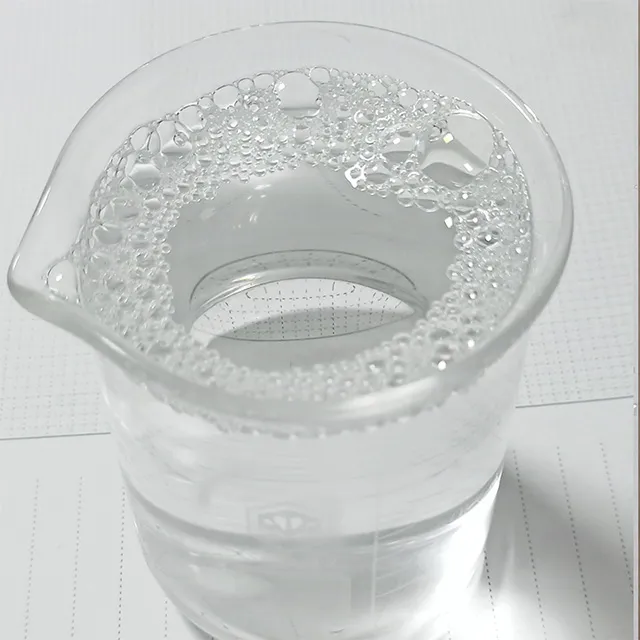

Acid etching additive is a chemical used for metal surface treatment. It reacts with the metal surface to remove the oxide layer and other impurities, thereby improving the metal's finish and coating adhesion. Its main functions include cleaning metal surfaces, improving metal surface quality, and promoting subsequent process effects.

2. Efficiency in mass production

In mass production, efficiency is one of the key indicators of process and material suitability. The use of acid etching additive can quickly remove oxides and contaminants from the metal surface and accelerate the surface treatment process. This fast, efficient processing is particularly important in large-scale production, as it improves the overall efficiency of the production line.

3. Impact of acid corrosion additive on the environment

As environmental awareness increases, consumers and industries are paying increasing attention to environmentally friendly products. In large-scale production, the use of acid corrosion additive may cause waste liquid treatment and discharge problems. Therefore, choosing environmentally friendly acid corrosion additives and taking corresponding waste liquid treatment measures are crucial to reducing environmental impact.

4. Selection of acid etching additive

In large-scale production, choosing the appropriate acid etching additive is crucial. Consumers and industries need to choose different types of acid etching additives based on specific metal types, processing needs and subsequent processes. For example, different acid etching additives are selected for different metal materials such as aluminum, copper, steel, etc. to ensure the best surface treatment effect.

5. Safety of acid etching additive

In large-scale production, the safety of acid etching additive is an issue that cannot be ignored. Since acid etching additive is usually corrosive, operators need to take appropriate safety precautions when using it. In addition, companies should also develop strict safety operating procedures to ensure the safety of workers and the production environment.

6. Cost-effectiveness of additives

In large-scale production, cost-effectiveness is one of the key considerations in business operations. The selection and use of acid etching additives should consider the balance between cost and effectiveness. Choosing an efficient and widely applicable acid etching additive can improve production efficiency and reduce production costs, thus improving the economic benefits of the enterprise.

7. Technical support for additives

In large-scale production, technical support is an important guarantee to ensure the applicability of acid etching additive. Choosing a supplier with a professional technical team and complete after-sales service can provide timely technical guidance and problem solutions during the production process to ensure the smooth progress of production.

8. Industry standards and specifications

When selecting and using acid corrosion additives, following industry standards and specifications is critical for large-scale production. Enterprises should refer to relevant standards and specifications to ensure that the quality, performance and safety of additives meet industry requirements, thereby ensuring the stable operation of the production line.

Conclusion

The applicability of acid corrosion additives in large-scale production is affected by many factors, including its characteristics, efficiency, environmental protection, safety, cost-effectiveness, technical support and industry standards. Choosing the appropriate acid corrosion additive to ensure the stability and efficiency of production is the key for enterprises to improve their competitiveness and meet market demand. Through comprehensive evaluation and careful selection, companies can give full play to the advantages of acid corrosion additives and achieve continuous improvement and development of production.