Will wax remover additive affect the coating effect of aluminum products?

2024-03-28 15:30

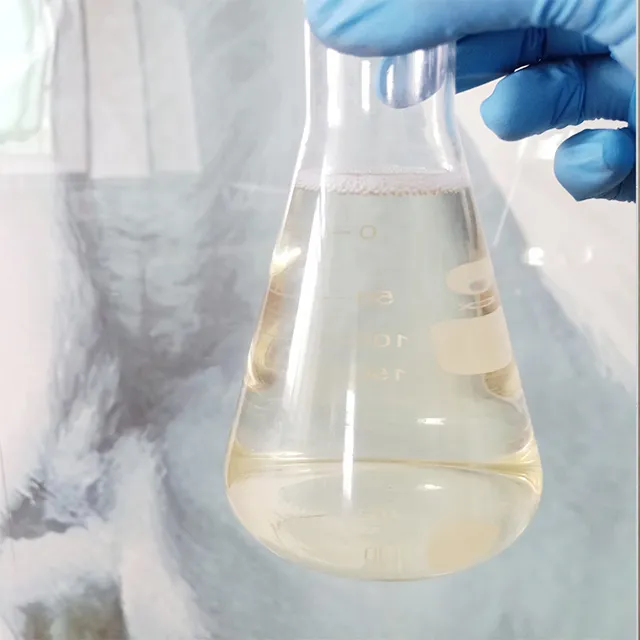

In the production and processing of aluminum products, wax removal additive is widely used as an important cleaning agent to remove wax, oil and dirt on the surface to improve the quality and performance of the product. However, a question that people are generally concerned about is whether wax remover additive will affect the coating effect of aluminum products? Today, we will delve deeper into this issue and analyze the potential impact of wax remover additive on the coating effect of aluminum products and the reasons why.

1. Cleaning function of wax remover additive

The main function of wax remover additive is to clean the surface of aluminum products, remove wax, oil and dirt on the surface, and restore its smoothness and brightness. This cleaning function can provide a good foundation for the coating of aluminum products and ensure good adhesion between the coating and the substrate.

2. The cleanliness of the surface of aluminum products affects the coating effect

The cleanliness of the surface of aluminum products is one of the important factors affecting the coating effect. A poorly clean surface will affect the adhesion and uniformity of the paint, leading to quality problems such as peeling and blistering on the painted surface. Therefore, the cleaning function of wax removal additive is crucial to improve the coating effect of aluminum products.

3. The residue of wax remover additive may affect the coating

Although wax remover additive effectively cleans aluminum surfaces, it may leave some residue behind during use. These residues may affect the adhesion and fluidity of the paint during the painting process, thus affecting the painting effect. Some residues may form defects on the surface after painting, such as bubbles, roughness, spots, etc.

4. Select the appropriate wax removal additive and coating process

In order to reduce the impact of wax remover additive on the painting effect, you can choose a suitable wax remover additive and painting process. First of all, you should choose wax removal additive with good quality and reasonable formula, and operate it in strict accordance with the production process requirements to avoid the generation of residues. Secondly, during the coating process, the appropriate coating process should be selected according to the actual situation, including coating selection, coating thickness, coating temperature and humidity, etc., to ensure the stability and consistency of the coating effect.

5. Strict quality control to ensure coating effect

In order to ensure the coating effect of aluminum products, strict quality control measures need to be implemented. This includes inspecting the quality of raw materials, strictly controlling and monitoring the coating process, and conducting quality inspection and evaluation of finished products. Only by ensuring that every link meets standard requirements can the stability and reliability of the coating effect be guaranteed.

6. Comprehensive considerations to ensure coating quality

To sum up, wax removal additive may affect the coating effect of aluminum products to a certain extent, but by selecting suitable additives and coating processes, strict quality control and other measures, the impact can be reduced and the coating quality can be ensured. Therefore, during the coating process of aluminum products, various factors need to be comprehensively considered to ensure the stability and reliability of the coating effect.