Why is alkali etching additive so important for aluminum surface treatment?

2024-02-24 15:35

Core challenges in aluminum surface treatment

In the production and processing of aluminum products, surface treatment is a crucial part. However, aluminum's high reactivity and easy oxidation make its surface treatment face many challenges. Among them, the application of basic etching additive is particularly important, as it provides key support for aluminum surface treatment. So, why is alkali etching additive so important for aluminum surface treatment? We will explore this issue in depth.

The mechanism of action of alkali etching additive

Alkali etching additive is a type of chemicals used for aluminum surface treatment. Its main components are usually alkaline substances, such as alkali metal hydroxides or alkaline salts. During the surface treatment process, the main function of basic etching additive is to remove the oxide film and impurities on the aluminum surface, thereby purifying the surface and creating good conditions for subsequent processing steps. Alkali etching additive achieves surface cleaning and purification by chemically reacting with metal oxides in the oxide film, dissolving or converting them into easily soluble substances, which are then rinsed away.

The key role of removing the oxide layer

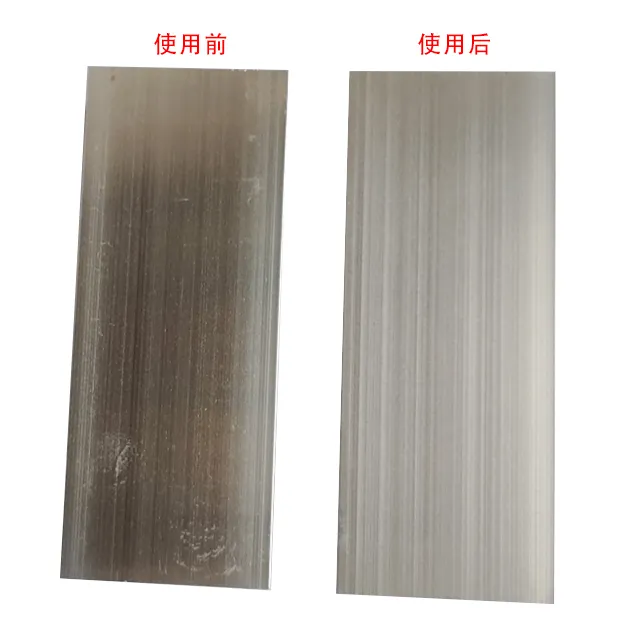

The oxide layer on the surface of aluminum is one of its greatest features, but it is also one of the main difficulties in surface treatment. The existence of the oxide layer not only affects the appearance and gloss of aluminum products, but also affects the adhesion and corrosion resistance of its surface. Therefore, removing the oxide layer has become one of the first tasks in aluminum surface treatment. In this process, alkali etching additive plays a vital role. It can effectively dissolve and remove the oxide layer, laying a good foundation for subsequent processing steps.

Key measures to improve surface quality

Surface quality is critical to the longevity and performance of aluminum products. By using alkali etching additive for surface treatment, the surface quality of aluminum products can be effectively improved. First of all, after the oxide layer and impurities are removed, the aluminum surface will become cleaner and smoother, which is beneficial to the adhesion of the coating and the decoration of the surface. Secondly, basic etching additive can also remove oil and dirt on the surface, making the surface treatment more thorough and even. These measures will help improve the appearance quality and service life of aluminum products.

Promote the smooth progress of subsequent processing processes

Aluminum surface treatment is a multi-step process in which each step requires basic support from the previous step. In this process, the role of alkali etching additive is not only to remove the oxide layer and impurities, but also to provide a good foundation for subsequent processing processes. For example, in anodizing, the aluminum surface that has removed the oxide layer and impurities will more easily form a uniform and dense oxide layer, thereby improving the quality and corrosion resistance of the oxide layer. Therefore, the role of alkali etching additive is not only to clean the surface, but also to provide support for the smooth progress of subsequent treatment processes.

Future prospects and development trends

As the performance requirements for aluminum products continue to increase, the research and application of alkali etching additives are also in-depth. In the future, with the development of technology and the emergence of new materials, the types and properties of basic etching additive will continue to be enriched and improved, providing more possibilities and opportunities for the continuous innovation and development of aluminum surface treatment technology. We look forward to seeing more breakthroughs and progress in this field, bringing greater benefits and development to the production and application of aluminum products.