Why do we need to use sealing additive agent after anodizing?

2024-02-22 15:30

Anodizing is a common metal surface treatment method that improves the corrosion resistance, hardness and aesthetics of the metal by forming an oxide film on the metal surface. This process is widely used in industrial production and daily life, but what are the considerations for the subsequent use of Sealing additive agent?

Characteristics and shortcomings of oxide layer

The oxide layer formed by anodizing treatment has certain pores and cracks. Although it can provide certain protection, there are still some hidden dangers. These tiny defects may lead to poor density of the oxide layer, reducing its corrosion resistance and wear resistance, thereby affecting the service life and performance of the metal products.

How Sealing additive agent works

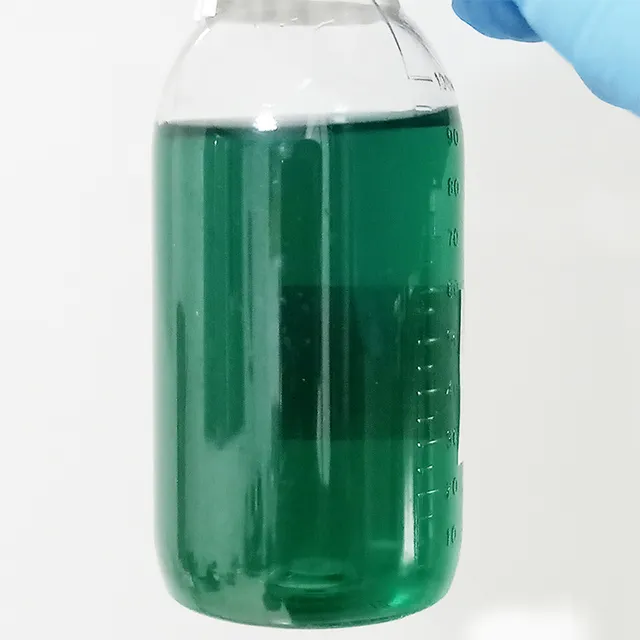

Sealing additive agent is a special chemical substance whose main component is usually organic polymers or silicone substances. After anodizing, the sealing agent is coated on the metal surface to form a dense sealing layer by filling the micropores and cracks in the oxide layer, thereby improving the sealing and corrosion resistance of the oxide layer.

Improve the corrosion resistance of the oxide layer

After adding a sealant, the sealing layer can effectively prevent the intrusion of moisture, oxygen and other harmful substances, further improving the sealing and corrosion resistance of the oxide layer. This protective layer can extend the service life of metal products, especially in humid and corrosive environments, and has significant effects.

Improve appearance and texture

Sealing additive agent can also improve the appearance and texture of the oxide layer. By selecting different types of sealing agents, the oxide layer can show different colors and glosses to meet the needs of different customers. This beautiful surface treatment effect can enhance the added value and market competitiveness of the product.

Improve the performance of metal products

In addition to improving corrosion resistance and improving appearance, sealing additive agents can also improve other properties of metal products. For example, adding an appropriate amount of sealant can reduce the resistivity of the oxide layer and improve its conductivity, which is beneficial to the use and processing of metal products.

Future development trends and challenges

As people's performance requirements for metal products continue to increase, the research and application of Sealing additive agents are also in-depth. In the future, the types and properties of sealing additive agents will continue to be enriched and improved, bringing more possibilities and opportunities to metal surface treatment. However, the selection, use and coordination of Sealing additive agents with other treatment processes still face some challenges and require further research and exploration.

Solutions and Outlook

The application of sealing additive agent after anodization can not only improve the corrosion resistance and aesthetics of the oxide layer, but also improve the overall performance of metal products. In the future, with the continuous advancement of technology and the accumulation of application experience, it is believed that Sealing agent will play an increasingly important role in the field of metal surface treatment, providing better quality metal products for all walks of life.