What is wax remover additive?

2024-06-06 15:30

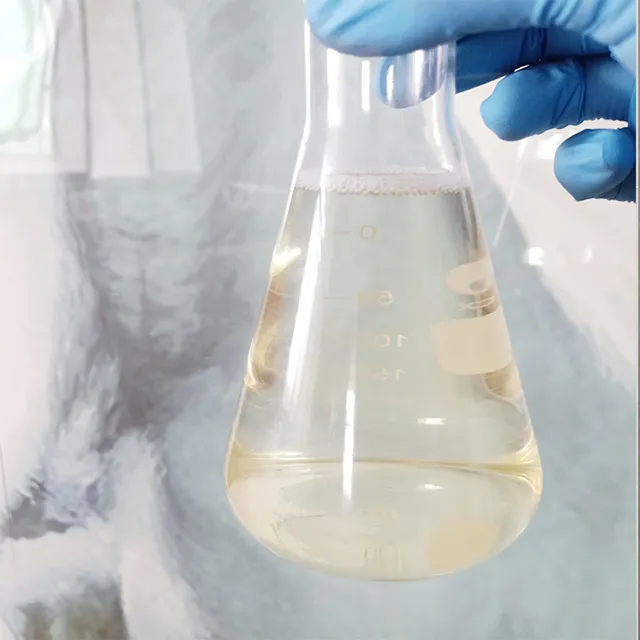

In the field of metal surface treatment, wax remover additive is an important chemical product that is often used to remove wax residues from metal surfaces. For many consumers and industry professionals, wax remover additive may be an unfamiliar term, and they may be curious about what this additive is and its role and significance in metal processing. Today, we will delve into the definition, ingredients, uses and importance of wax remover additive in metal processing, and unveil the mystery of this field for everyone.

What is wax remover additive?

Wax removing additive is a chemical additive used to remove wax residues from metal surfaces. During metal processing and processing, waxy residues are often present on metal surfaces, especially when processing materials such as aluminum products. These waxy residues may come from coating agents, protective films or wax materials used in other processing processes. They will affect the quality and coating effect of the metal surface, so they need to be completely removed.

Ingredients and principles of wax remover additive

Wax removing additive is usually composed of a variety of chemical components, which mainly include solvents, surfactants and auxiliaries. These ingredients effectively dissolve and disperse waxy residues on metal surfaces, removing them completely. Solvents are soluble and volatile, allowing them to quickly dissolve waxy residue and lift it from metal surfaces. Surfactants reduce the adhesion of waxy residue to metal surfaces, making them easier to clean. Additives can improve the cleaning effect and stability of wax remover additive.

The working principle of wax remover additive is to completely remove wax residues on the metal surface through chemical dissolution and physical cleaning. During the processing, wax remover additive is applied or sprayed on the metal surface. After a certain period of time, the wax residue is effectively dissolved and removed, and the metal surface becomes clean and smooth, providing good conditions for subsequent processing and painting. A good foundation.

Application of wax removing additive in metal processing

Wax remover additive plays an important role in metal processing and is widely used in multiple processes, including cleaning, pretreatment and painting. In the processing of aluminum products, wax removal is a common process step. It can effectively remove wax residues on the aluminum surface, improve the surface quality and coating effect of aluminum products, thereby enhancing its appearance and durability.

In addition, wax removing additive is also commonly used in the processing and treatment of other metal materials, such as stainless steel, magnesium alloy, etc. During the processing of these materials, wax removal can also play a role in cleaning and pretreatment, providing good surface conditions and foundation for subsequent processing and painting.

Summarize

To sum up, wax removing additive is an important metal surface treatment chemical that can effectively remove wax residues on the metal surface and improve its surface quality and coating effect. In metal processing and processing, wax remover additive plays an important role, providing reliable guarantee for product quality and performance.