What is the temperature for anodizing with dyes?

2024-07-02 15:30

Anodizing is a process widely used in the surface treatment of aluminum products. It forms a thick and strong oxide film on the aluminum surface through an electrolytic process. This oxide film not only has good corrosion resistance and wear resistance, but also can achieve colorful decorative effects through the addition of dyes.

In the anodizing process, temperature is an important factor affecting the dyeing effect and the quality of the oxide film. This article will discuss in detail the temperature range of anodizing with dyes and its impact on the process effect.

What is the basic principle of anodizing?

Anodizing is the process of using electrolyte solution to generate an aluminum oxide film on the surface of aluminum through an applied voltage. The formation of this oxide film not only improves the hardness and corrosion resistance of aluminum, but also increases its surface adsorption capacity, enabling it to absorb various dyes and achieve a variety of colors of decorative effects.

The process steps of anodizing mainly include:

1. Pretreatment: cleaning and degreasing to remove impurities and oxides on the surface of aluminum.

2. Anodizing: electrolysis in sulfuric acid solution to form a porous aluminum oxide film.

3. Dyeing: immerse the oxide film in the dye solution and achieve the dyeing effect through adsorption.

4. Sealing: Through hot water or steam treatment, the pores of the oxide film are sealed to improve its corrosion resistance and wear resistance.

What is the temperature of anodizing?

During the anodizing process, temperature is a key factor affecting the dyeing effect and the quality of the oxide film. Different temperature conditions will lead to significant differences in the dyeing effect and the performance of the oxide film. Generally speaking, the temperature range for anodizing with dyes is 15℃ to 30℃, and the specific temperature selection depends on the following factors:

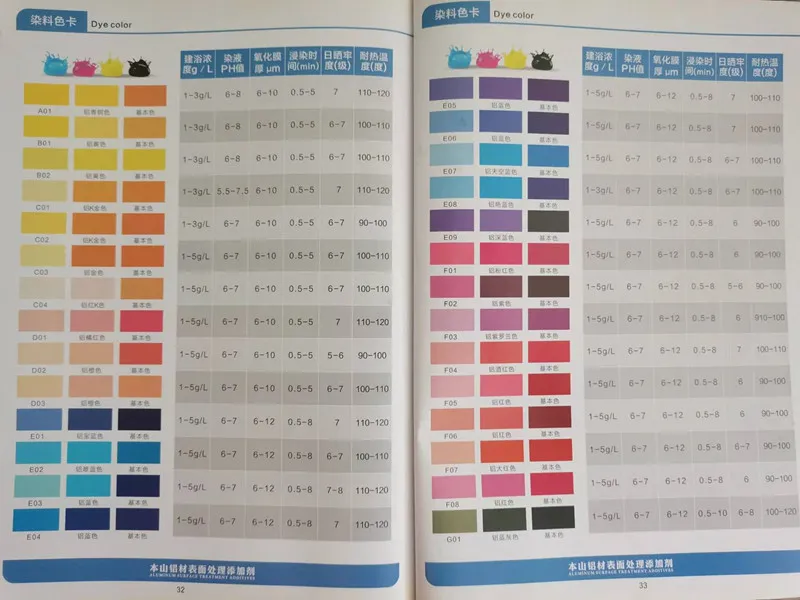

1. Dye type: Different types of dyes have different sensitivities to temperature. Organic dyes and inorganic dyes have different adsorption effects and color stability at different temperatures.

2. Oxide film thickness: Thicker oxide films usually require lower temperatures to avoid too fast oxidation reactions, thereby ensuring the density and uniformity of the oxide film.

3. Process requirements: Depending on the specific application requirements, anodizing may need to be performed within a specific temperature range to obtain the ideal dyeing effect and oxide film performance.

What is the anodizing effect under different temperature conditions?

1. Low temperature anodizing (15℃ to 20℃):

Low temperature anodizing is suitable for application scenarios that require high hardness and high wear resistance. Anodizing in the temperature range of 15℃ to 20℃ can form a dense and uniform oxide film with good corrosion resistance and mechanical properties. However, under low temperature conditions, the adsorption rate of the dye is slow, and a longer dyeing time may be required to achieve the desired color effect.

Advantages:

● The oxide film is dense and has good wear resistance.

● The dyeing effect is stable and the color is uniform.

Disadvantages:

● The dyeing time is long and the production efficiency is low.

● The temperature control requirements are high and the process is more complicated.

2. Medium-temperature anodizing (20℃ to 25℃):

Medium-temperature anodizing is the most commonly used temperature range and is suitable for most industrial and decorative applications. Anodizing in the temperature range of 20℃ to 25℃ can achieve better oxide film quality and dyeing effect. The oxidation reaction rate in this temperature range is moderate, and a uniform oxide film can be formed, and the adsorption effect of the dye is also ideal.

Advantages:

● Wide range of application and stable process.

● Good dyeing effect and bright color.

● High production efficiency.

Disadvantages:

● High temperature control requirements, constant temperature conditions need to be maintained.

3. High temperature anodizing (25℃ to 30℃):

High temperature anodizing is suitable for applications that require rapid production and bright colors. Anodizing in the temperature range of 25℃ to 30℃ has a faster oxidation reaction rate, which can shorten the production cycle. However, the oxide film under high temperature conditions may be loose, with slightly lower corrosion resistance and wear resistance, and appropriate post-treatment is required to improve the film performance.

Advantages:

● Short production cycle and high efficiency.

● Good dyeing effect and bright colors.

Disadvantages:

● The oxide film is relatively loose and has low corrosion resistance.

● Post-treatment needs to be strengthened to improve the film performance.

What is the effect of temperature on the effect of anodizing dyeing?

The effect of temperature on the effect of anodizing dyeing is mainly reflected in the following aspects:

1. Dye adsorption rate: At lower temperatures, the adsorption rate of dyes is slower, and it takes a longer time to achieve the ideal dyeing effect. At higher temperatures, the adsorption rate of dyes is faster, and bright color effects can be achieved in a short time.

2. Color uniformity: Improper temperature control may lead to uneven dyeing. Dyeing at lower temperatures is usually more uniform, while dyeing at higher temperatures is prone to uneven colors, which needs to be solved through strict process control.

3. Oxide film quality: Temperature has a significant impact on the quality of the oxide film. The oxide film formed at a lower temperature is usually denser and has good corrosion resistance and wear resistance. The oxide film formed at a higher temperature may be looser and needs to be sealed to improve its performance.

Conclusion

Temperature plays a vital role in the anodizing dyeing process. By reasonably controlling the temperature, ideal dyeing effects and excellent oxide film quality can be achieved.

In actual production, enterprises need to select the appropriate temperature range according to specific process requirements and product characteristics, and optimize the process and equipment to achieve the best production effect.