What is the role of anodized dye in metal processing?

2024-03-05 15:30

Anodizing is a common metal surface treatment technology, and anodized dye is a substance widely used in this process. However, many people still have doubts about the role of anodizing dye powder and its importance in metal processing. Today, we’ll delve deeper into the subject and reveal the true role of anodized dye in metal treatment.

1. Improve product appearance: add color and gloss

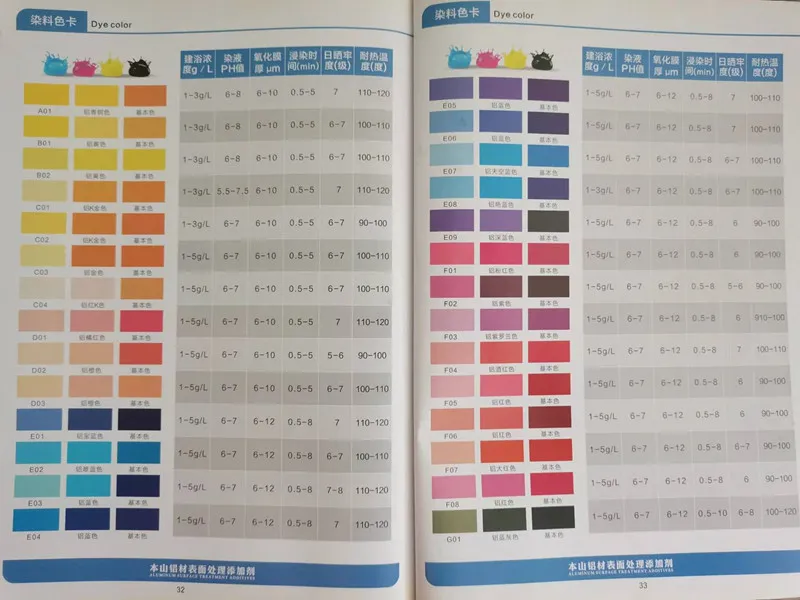

Anodizing dye powder can give metal products rich colors and unique luster. By selecting different types of dyes and adjusting parameters such as dye concentration and processing time, a variety of colors can be formed on the metal surface, such as black, gold, blue, etc., making the product appearance more colorful and attractive.

2. Improve corrosion resistance: form a stable oxide layer

Anodized dye can help form a more stable and dense oxide layer. This oxide layer can not only increase the hardness and wear resistance of metal products, but also effectively prevent oxygen, moisture and other corrosive media from corroding the metal, improve the corrosion resistance of metal products, and extend the service life.

3. Improve surface quality: improve surface flatness

The function of anodizing dye powder also includes improving the flatness and smoothness of metal surfaces. During the anodizing process, the dye enters the micropores on the metal surface and fills the surface unevenness, making the surface smoother and more uniform. This not only helps improve the appearance quality of the product, but also helps improve the effects of subsequent painting and processing processes.

4. Increase decorative effect: achieve personalized customization

Anodized dye can also be used to achieve personalized customization and decorative effects on metal products. By adjusting the color and concentration of the dye, metal products of different styles and styles can be customized according to customer needs, meeting the personalized needs of different user groups and increasing the market competitiveness of the product.

5. Environmental protection and sustainability: reduce pollution emissions

Compared with traditional metal surface treatment methods, anodizing dye powder has lower environmental pollution and energy consumption. Most of the dyes used in the anodizing process are environmentally friendly organic substances and have little impact on the environment. At the same time, anodizing can realize the recycling of metal surfaces, which is in line with the concept of sustainable development.

Conclusion: anodized dye helps improve the quality of metal processing

Anodizing dye powder plays an irreplaceable role in metal processing. It can not only enhance the appearance of the product, increase corrosion resistance, improve surface quality, but also increase the decorative effect, while being environmentally friendly and sustainable. Therefore, in the production and processing of metal products, the correct selection and use of anodized dye is an important measure to ensure product quality and environmental friendliness.