What is the effect of wax remover additive on the wear resistance of aluminum products?

2024-06-24 15:30

In the surface treatment process of aluminum products, wax remover additive is a crucial component. It can not only remove wax on the surface, but also affect the wear resistance of aluminum products. Wear resistance is one of the important characteristics of aluminum products when facing friction and wear during use.

This article will explore the effect of wax remover additive on the wear resistance of aluminum products in depth to meet the concerns of consumers and the industry about product quality.

1. The role of wax removing additive

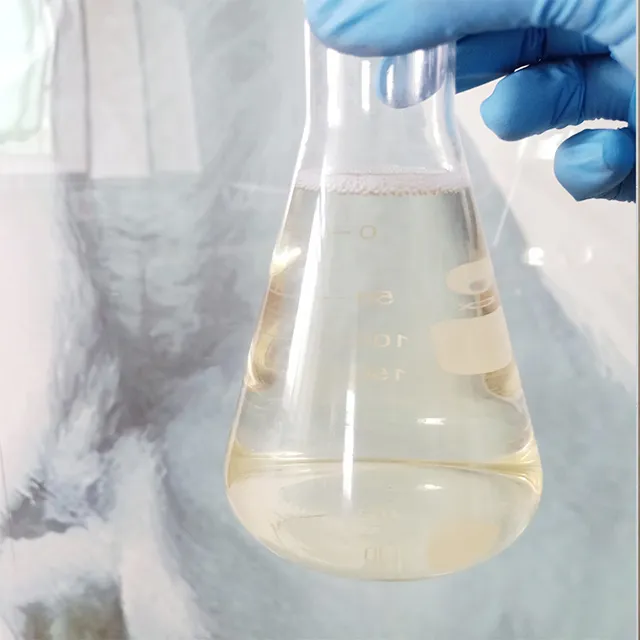

Wax remover additive is a chemical used to remove wax and dirt from the surface of aluminum products. In the production process of aluminum products, it is often necessary to dewax them to ensure the surface is clean and convenient for subsequent processing and treatment.

2. The importance of wear resistance

Wear resistance is one of the important indicators to measure the quality of aluminum products. Aluminum products often encounter friction and wear during use. If their wear resistance is poor, it will cause problems such as surface wear and scratches, affecting the appearance and service life of the product.

3. The effect of wax removing additive on wear resistance

Wax remover additive will have a certain impact on the surface of aluminum products while removing wax. Some additives may leave a film or chemical residue on the surface, which may affect the surface quality and wear resistance of aluminum products.

4. Effect of chemical composition on wear resistance

The chemical composition of wax remover additive may enhance the hardness and wear resistance of aluminum surface, making it more resistant to friction and wear; while other chemical compositions may reduce the wear resistance of aluminum products, making them more susceptible to surface damage.

5. Effect of additive concentration and treatment method

The concentration and treatment method of wax remover additive also affect its effect on the wear resistance of aluminum products. Appropriate additive concentration and treatment method can ensure that wax is removed without affecting the surface quality and wear resistance of aluminum products.

6. Wear resistance test method

For the wear resistance of aluminum products, a series of tests are often required, including friction tests, wear tests, etc. These tests can help evaluate the wear resistance of aluminum products, thereby guiding the selection of additives and treatment methods in the production process.

7. Consumer concerns

When choosing aluminum products, consumers often pay attention to their wear resistance. An aluminum product with good wear resistance can not only maintain long-term beauty, but also extend its service life and reduce maintenance costs.

8. Industry development trend

As consumers' requirements for product quality increase, the aluminum product manufacturing industry is also constantly pursuing better wear resistance. Therefore, developing better quality wax removing additives to improve the wear resistance of aluminum products has become one of the development trends of the industry.

Conclusion

Wax remover additive has an important impact on the wear resistance of aluminum products. Consumers and the industry need to recognize this and fully consider the factors of wear resistance in product selection and production. By scientifically and rationally selecting additives and treatment methods, it is possible to ensure that aluminum products have good wear resistance, thereby improving product quality and competitiveness.