What is the best solution for etching aluminum?

2024-07-12 15:30

Aluminum surface treatment technology is particularly critical, and etching process is one of the important means. Etching aluminum can not only change its surface properties, but also form specific patterns or structures, giving aluminum higher added value.

So, what is the best solution for etching aluminum? This article will explore this issue in depth, analyze the advantages and disadvantages of various etching solutions, and interview many industry experts to provide comprehensive industry insights.

What is the basic principle of aluminum etching?

Etching is a process that removes part of the material surface through chemical reactions. In aluminum etching, acidic or alkaline solutions mainly react with aluminum to dissolve the surface layer and form the desired texture or pattern. The choice of etching solution directly affects the etching effect, including etching speed, surface finish and impact on the environment.

What are the common etching solutions?

At present, the commonly used aluminum etching solutions in industrial production are mainly: hydrofluoric acid (HF), nitric acid (HNO3), phosphoric acid (H3PO4), ferric chloride (FeCl3), and alkaline solutions (such as sodium hydroxide NaOH). Each solution has its unique advantages and scope of application.

1. Hydrofluoric acid (HF):

Hydrofluoric acid is a strong solution for etching aluminum. It can quickly dissolve aluminum and its oxides to form a smooth and fine etched surface. The main advantage of hydrofluoric acid is its efficient etching ability, which is suitable for occasions requiring high precision and fast processing. However, its high corrosiveness and high toxicity also bring challenges in terms of safety and environmental protection.

2. Nitric acid (HNO3):

Nitric acid is often mixed with hydrofluoric acid to form a strong etching solution. Nitric acid can not only remove the oxide layer on the surface of aluminum, but also provide an oxidant to promote the dissolution of aluminum. The etching speed of nitric acid solution is moderate, which can achieve a relatively uniform etching effect, but its strong acidity also requires strict safety operation and waste liquid treatment.

3. Phosphoric acid (H3PO4):

Phosphoric acid is a relatively mild etching solution, suitable for delicate and uniform etching needs. Phosphoric acid etching does not produce violent reactions, which is suitable for aluminum products with high surface quality requirements. However, phosphoric acid has a slow etching speed and is suitable for processes that require a longer etching time.

4. Ferric chloride (FeCl3):

Ferric chloride is an etching solution widely used in the electronics industry, especially in the manufacture of printed circuit boards (PCBs). Ferric chloride can provide precise etching control to ensure fine and accurate patterns. Although the etching rate of ferric chloride is moderate, its waste liquid treatment is relatively complicated and special attention should be paid to environmental protection requirements.

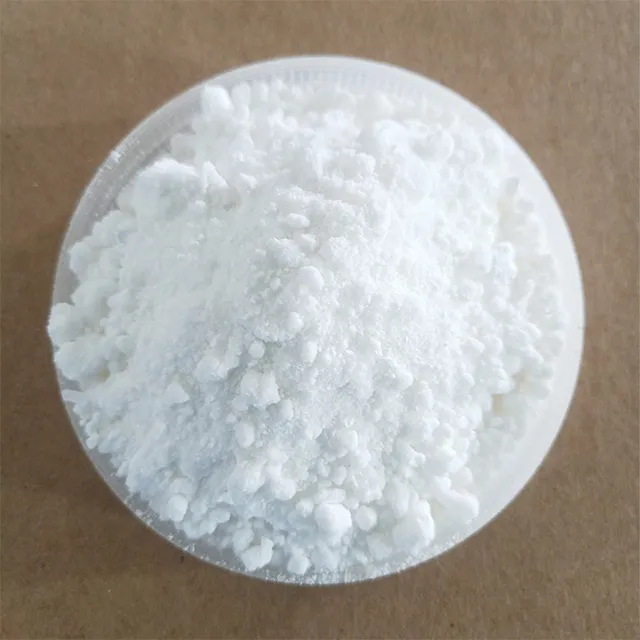

5. Alkaline solutions (such as sodium hydroxide NaOH):

Alkaline solutions, such as sodium hydroxide solutions, are also used for aluminum etching. Sodium hydroxide solutions can effectively remove the oxide layer and impurities on the surface of aluminum, forming a uniform etching effect. The advantages of alkaline solutions are their relatively low toxicity and relatively simple waste liquid treatment. However, alkaline etching speed is slow and has a certain degree of corrosiveness to etching equipment.

What is the best solution for etching aluminum?

In order to evaluate the effects of various etching solutions, we compared the performance of several common etching solutions on different aluminum materials. During the experiment, aluminum samples with equal thickness and equal surface treatment were selected and etched in hydrofluoric acid, nitric acid-hydrofluoric acid mixed solution, phosphoric acid, ferric chloride and sodium hydroxide solutions respectively.

1. Etching speed:

HF and nitric acid-hydrofluoric acid mixed solution show the fastest etching speed, and a significant etching effect can be formed in a short time. The etching speed of ferric chloride and phosphoric acid is moderate, while the etching speed of sodium hydroxide solution is the slowest.

2. Surface finish:

The surface finish of aluminum after etching with HF and nitric acid-hydrofluoric acid mixed solution is high, which is suitable for processes requiring high precision. The surface after phosphoric acid etching is relatively uniform, which is suitable for products with high requirements for surface quality. The surface finish etched by ferric chloride solution is moderate, which is suitable for electronic device manufacturing. The surface finish etched by sodium hydroxide solution is low, which is suitable for industrial use.

3. Environmental protection and safety:

Nitric acid-hydrofluoric acid mixed solution and hydrofluoric acid are highly corrosive and toxic, and strict safety operation and waste liquid treatment are required. The safety of ferric chloride and phosphoric acid is relatively good, but environmental protection requirements still need to be paid attention to. The environmental protection and safety of sodium hydroxide solution are better, and the waste liquid treatment is relatively simple.

Conclusion

HF and nitric acid-hydrofluoric acid mixed solution are suitable for occasions requiring high precision and fast processing, but safety and environmental protection issues need to be paid attention to. Phosphoric acid is suitable for products with high surface quality requirements, while ferric chloride performs well in the manufacture of electronic devices. Although the etching speed of NaOH solution is slower, it has advantages in environmental protection and safety.