What is Sealing additive? What is its role in aluminum surface treatment?

2024-02-21 15:30

In recent years, with the continuous development of industrial technology, aluminum and its alloys have been increasingly used in various fields. As an important technology in the field of metal surface treatment, anodization plays an important role in improving the surface properties of aluminum materials. In response to the problems existing in the anodizing process, our company actively carried out research and development work and successfully developed a series of Sealing agents, which injected new vitality and possibility into aluminum surface treatment.

What is Sealing additive agent?

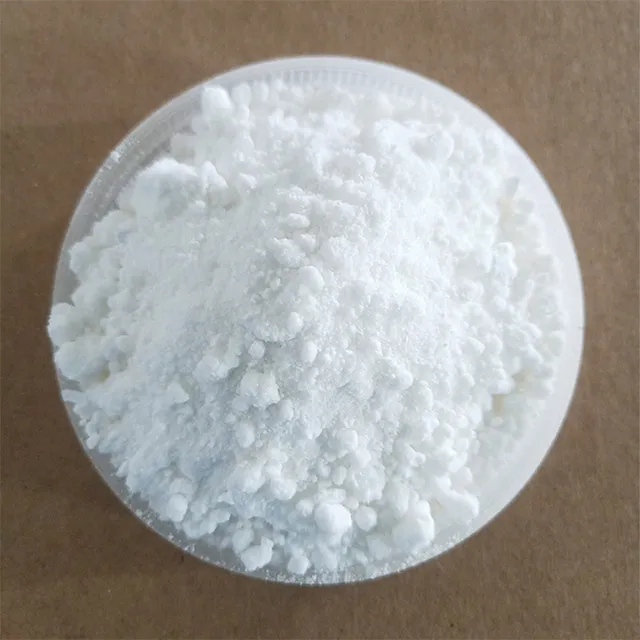

Sealing additive agent, as the name suggests, is an auxiliary agent used in the sealing process of anodized aluminum surfaces. It is usually a chemical substance that can form a uniform and dense oxide layer under certain conditions, thereby improving the surface properties of aluminum materials and enhancing its corrosion resistance, wear resistance and other properties.

What is the role of sealing agent in aluminum surface treatment?

Sealing additive agent plays a vital role in aluminum surface treatment. First, it can fill the micropores and cracks in the anodized layer, forming a dense protective film on the surface, thereby improving the corrosion resistance of the aluminum material.

Secondly, Sealing agent can also improve the mechanical properties of the surface, increase its hardness and wear resistance, and extend the service life of aluminum products.

In addition, Sealing agent can also improve the electrical insulation performance of the aluminum surface, reduce static electricity accumulation, and help improve the electrical performance and safety of aluminum products.

Our company’s research and development and application of Sealing additive agent

As a high-tech enterprise focusing on metal surface treatment products, our company has always been committed to the research and development and innovation of new products. In response to the demand for sealing processes in aluminum surface treatment, we have invested a lot of manpower and material resources to successfully develop a series of high-performance sealing additive agents and apply them in actual production.

After many tests and improvements, our Sealing agent has not only achieved remarkable results in improving the surface properties of aluminum products, but also made important breakthroughs in production cost and process control, and has been well received by customers.

Future Outlook: The Development Direction of Sealing Additive Agent

With the wide application of aluminum materials in aviation, automobiles, construction and other fields, the requirements for surface treatment technology are becoming higher and higher. In the future, our company will continue to increase investment in research and development of Sealing additive agents, continuously optimize product performance, and expand application areas.

At the same time, we will also conduct in-depth research on the mechanism and control methods of the sealing process, strive to improve production efficiency, reduce costs, provide customers with better products and services, and make greater contributions to the development of aluminum surface treatment technology.

Conclusion

The development and application of sealing additive agent has injected new vitality and possibility into aluminum surface treatment technology, providing important support for the performance improvement and application expansion of aluminum products. Our company will continue to adhere to the concept of technological innovation, continue to explore and move forward, contribute to the development of the field of metal surface treatment, and create greater value for customers.