What is alkali etching additive?

2024-05-27 15:30

Alkali etching additive is a chemical agent commonly used in the field of metal surface treatment. It plays an important role in the processing of aluminum products. However, basic etching additive may be an unfamiliar term to many consumers and industry people, and they may be curious about what this additive is and its role and significance in metal processing.

Today, we will delve into the definition, composition, use and importance of alkali etching additive in metal processing, and unveil the mystery of this field for everyone.

What is alkali etching additive?

Alkali etching additive, as the name suggests, is a chemical additive used for alkali etching treatment of metal surfaces. It usually consists of a variety of chemicals, including ingredients such as alkalis and etchants. In the processing of aluminum products, alkali etching additive is widely used in the processes of cleaning, removing oxide layers and improving surface quality. Compared with traditional mechanical processing methods, alkali etching treatment can be more efficient, save energy, and can process complex shapes and small structures, so it has been widely used in the metal processing industry.

The composition and principle of alkali etching additive

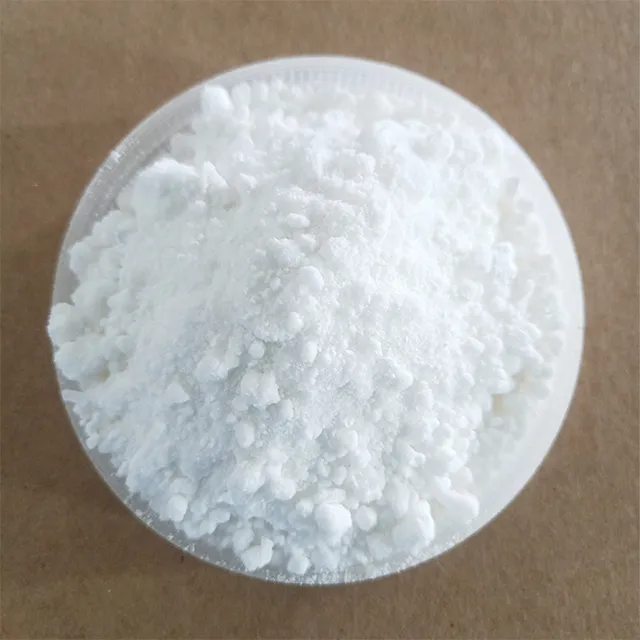

The composition of alkali etching additive is diverse and may vary according to different manufacturers and product formulas. However, usually, the main ingredients of alkali etching additive include alkaline substances (such as sodium hydroxide, potassium hydroxide, etc.) and etching agents (such as nitric acid, phosphoric acid, etc.). These chemical components can effectively dissolve oxides and dirt on the metal surface, making it easier to handle and process during subsequent processing.

The working principle of alkali etching additive is mainly to dissolve or remove oxides and other pollutants on the metal surface through chemical corrosion, thereby exposing a clean and smooth base material on the metal surface. During the corrosion process, alkaline substances neutralize acidic substances, while etchants can accelerate the dissolution reaction on the metal surface and increase the corrosion speed and efficiency. In this way, alkali etching additive can effectively improve the quality and smoothness of metal surfaces, providing a good foundation for subsequent processing steps.

Application of basic etching additive in metal processing

In metal processing, alkali etching additive is widely used in multiple processes, including cleaning, etching and pretreatment of aluminum profiles, aluminum plates, aluminum alloys and other aluminum products. In the production of aluminum profiles, alkali etching treatment is often an important link. It can effectively remove oxide scale, oil stains and impurities on the aluminum surface, improve the surface quality and adhesion of aluminum profiles, thereby enhancing its corrosion resistance and use. life. In the processing of aluminum plates and aluminum alloys, alkali etching treatment also plays a similar role, providing good surface conditions and processing foundation for subsequent anodizing, coating and finishing processes.

Summarize

To sum up, basic etching additive is a chemical agent commonly used for metal surface treatment. It can effectively clean, remove oxide layers and improve metal surface quality through chemical corrosion, providing good conditions for subsequent processing and treatment processes. Foundation.

In the processing of aluminum products, alkali etching treatment plays an important role, which can improve product quality, increase production efficiency, and comply with environmental protection and energy saving requirements. With the continuous development and advancement of science and technology, I believe that the application prospects of alkali etching additive in the field of metal processing will be broader, injecting new vitality and power into the sustainable development and innovation of the industry.