What is a quick sealing additive?

2024-07-05 15:30

As a new type of material, quick sealing additive (QSA) is rapidly emerging and providing efficient and reliable solutions for various engineering projects.

This article will explore the background, principle, application and future development prospects of this innovative material.

What is a quick sealing additive?

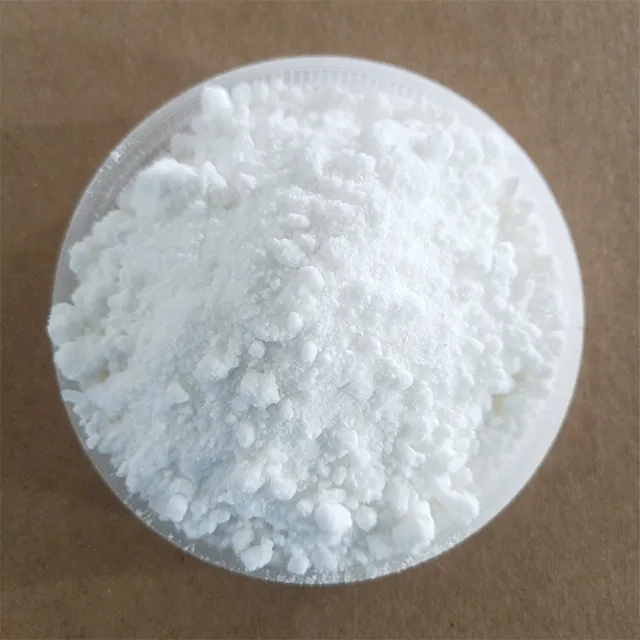

A quick sealing additive is a material that can achieve a sealing effect in a relatively short time. It is usually added to other base materials to enhance their sealing performance, reduce leakage and extend service life. Quick sealing additives are widely used in automobile manufacturing, construction engineering, pipeline repair and other fields, and have received widespread attention due to their high efficiency and reliability.

Background and development of quick sealing additives

The concept of quick sealing additives originates from the dual needs of engineering construction efficiency and quality. In the traditional construction process, sealing materials often require a long curing time, which not only delays the progress of the project, but also may cause unsatisfactory sealing effects due to environmental factors. In order to solve these problems, scientists and engineers began to develop materials that can complete the sealing work in a short time, which is the origin of quick sealing additives.

The research on quick sealing additives began in the late 20th century. With the development of nanotechnology and chemical materials science, this field has made significant progress. Nowadays, fast sealing additives have been widely used in many fields such as construction, roads, pipeline repair, and ship repair.

What is the principle of fast sealing additives?

The working principle of fast sealing additives is mainly based on its unique chemical composition and reaction mechanism. Its core components usually include high molecular polymers, nanoparticles and active catalysts. The following are its main characteristics:

1. Efficient curing: Fast sealing additives can complete curing in a short time, usually only a few minutes to tens of minutes. This is mainly due to the fact that the catalyst inside it can quickly trigger a chemical reaction, causing the sealing material to harden quickly.

2. High strength and elasticity: The cured sealing material has high strength and good elasticity, can resist external pressure and temperature changes, and ensure the durability of the sealing effect.

3. Chemical resistance: Fast sealing additives usually have good chemical corrosion resistance and are suitable for various harsh environments.

Application fields of fast sealing additives

The application range of fast sealing additives is very wide. The following are some of the main application fields:

1. Construction engineering: In construction, fast sealing additives can be used for wall crack repair, roof waterproofing, foundation sealing, etc. Its fast curing characteristics can greatly shorten the construction time and improve construction efficiency.

2. Road repair: In road repair, fast sealing additives are widely used for crack repair and pothole filling. Traditional repair materials require a long time to solidify, while the use of fast sealing additives can restore road traffic in a short time, reducing traffic jams and construction costs.

3. Pipeline repair: In the fields of oil, natural gas, water treatment, etc., pipeline leakage is a common problem. Fast sealing additives can quickly repair pipeline cracks, prevent leakage, and ensure the normal production and life.

4. Ship repair: Ships often encounter various damages during navigation. Fast sealing additives can quickly repair hull damage at sea to ensure the safety and timeliness of the ship.

What are the advantages of fast sealing additives?

Compared with traditional sealing materials, fast sealing additives have the following significant advantages:

1. Fast construction speed: As the name suggests, the biggest advantage of fast sealing additives is that they have an extremely fast construction speed and can complete the sealing work within a few minutes to tens of minutes. This is especially important for time-sensitive engineering projects.

2. Wide application range: Due to its excellent weather resistance and chemical resistance, fast sealing additives can be used in various harsh environments, whether it is high temperature, low temperature or high humidity environment, it can perform excellent performance.

3. Easy operation: Fast sealing additives are usually supplied in pre-mixed or single-component form. When used, there is no need for complicated proportioning and mixing process. It only needs to be simply applied or injected, which greatly reduces the construction difficulty and labor cost.

4. Environmentally friendly: Modern fast sealing additives focus on environmental protection performance during the research and development process. Many products use solvent-free formulas to reduce pollution to the environment and meet the requirements of sustainable development.

Conclusion

As an innovative engineering material, fast sealing additives are changing the traditional construction method. Its high efficiency, convenience and multifunctionality make it show great application potential in many fields such as construction, roads, pipelines and ships.