What effect does chemical polishing additive have on aluminum surface coating?

2024-03-13 15:30

The importance of aluminum surface treatment technology

In modern industry, aluminum and its alloys are widely used in various fields, such as aerospace, automobile manufacturing, construction, etc. However, the surface treatment of aluminum is crucial as it directly affects the appearance, corrosion resistance and mechanical properties of the product. As an important part of surface treatment, chemical polishing compound has an important impact on the coating of aluminum surfaces.

Basic functions of chemical polishing agent

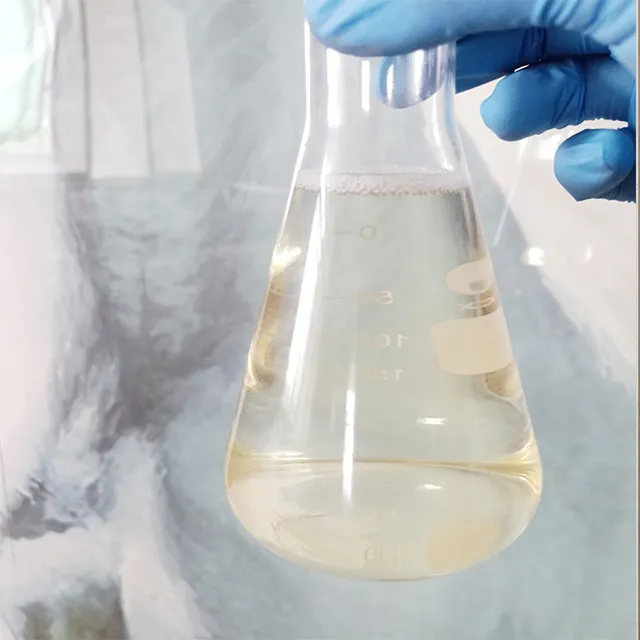

Chemical polishing additive is a special chemical agent used in the surface treatment process. Its main function is to improve the smoothness and brightness of the metal surface. In aluminum surface treatment, by adding an appropriate amount of chemical polishing compound, the coating surface can be made smoother and more uniform, and its surface quality and appearance can be improved.

Affects the gloss and flatness of the coating

The effect of chemical polishing agent on aluminum surface coating is mainly reflected in improving its gloss and flatness. By appropriately adjusting the composition and concentration of the additives, the microscopic morphology of the coating surface can be controlled, making it present a more uniform and detailed smooth surface, thus improving the gloss and flatness of the coating.

Promote chemical reactions

In addition, chemical polishing additive can also serve as a catalyst or activator to promote surface chemical reactions. During the aluminum surface treatment process, some chemical polishing compounds can react chemically with the metal surface to form a dense protective film to improve the adhesion and corrosion resistance of the coating.

Modulate surface charge and surface energy

Chemical polishing additive can also adjust the charge and surface energy of the metal surface, improving its wettability and adhesion. By changing the chemical properties of the surface, the coating can be more easily interacted with other substances during the treatment process, improving the adhesion and stability of the coating.

Improve production efficiency and reduce costs

In industrial production, the use of chemical polishing agents can improve production efficiency and reduce costs. Because chemical polishing additive can improve the finish and flatness of the coating, it can reduce manual handling and energy consumption in subsequent processing steps, thus saving production costs and improving production efficiency.

Strengthen environmental awareness and choose green additives

Although chemical polishing compounds play an important role in aluminum surface treatment, their impact on the environment also needs to be concerned. Therefore, strengthening environmental awareness and choosing green and environmentally friendly chemical polishing agents is one of the important directions for the development of the current aluminum surface treatment industry. Through continuous innovation and technological progress, we believe that more environmentally friendly and efficient surface treatment methods can be found, bringing more benefits to the production and application of aluminum products.