My aluminum products have gray deposits, can ash removal additive solve it?

2024-02-29 15:40

Frequent problems with aluminum products: gray precipitation troubles

Recently, some users of aluminum products have reported that unknown gray precipitates appear on the surface of their products, which has aroused widespread concern and concern among consumers. This problem not only affects the aesthetics of the product, but may also adversely affect the quality and performance of the product. When faced with this problem, people began to explore whether there was a solution, among which ash removing additive attracted much attention.

Surface precipitation phenomenon triggers heated discussion

Aluminum products, as a common metal material, are widely used in daily life and industrial production. However, the recent emergence of gray sedimentation has become the focus of attention. Some consumers have reported that the aluminum products they purchased, such as kitchen utensils and home decorations, have gray deposits on the surface that are difficult to remove, seriously affecting the appearance and use experience of the products.

Looking for solutions: ash removal additive becomes the focus

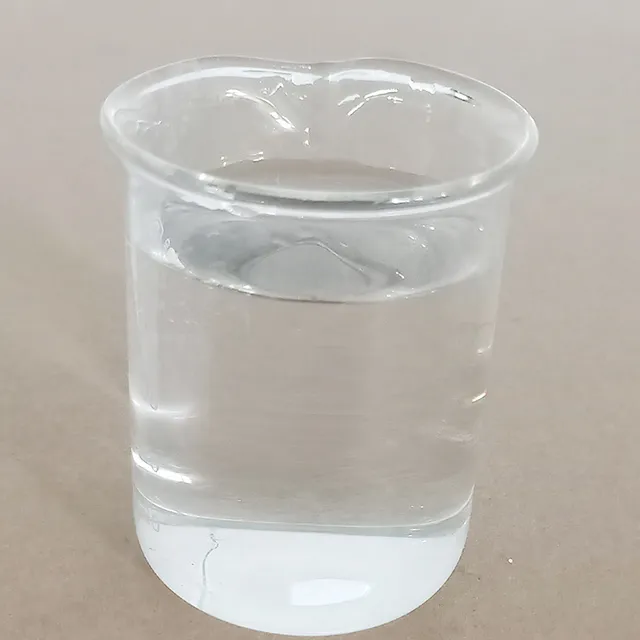

Faced with the problem of gray precipitation in aluminum products, people began to actively explore solutions. Among the many possible methods, ash removal additive has attracted much attention. As a common surface treatment agent, ash removing additive is widely used in the production and processing of metal products. Its main function is to remove the oxide film and impurities on the metal surface, making the metal surface smoother and cleaner.

Can ash removal additive solve gray precipitation?

However, industry insiders have different opinions on whether ash removal additive can solve the problem of gray precipitation on the surface of aluminum products. Some experts and manufacturers believe that ash removal additive can eliminate or reduce the problem of gray precipitation on aluminum products by removing oxide films and impurities on the surface. Other experts said that the gray precipitation may be related to the material or manufacturing process of the aluminum product itself, and ash removal additive may not be able to fundamentally solve this problem.

Practice test: How effective is ash removal additive?

In order to verify the effectiveness of ash removing additive in solving the gray precipitation problem of aluminum products, some related experiments have been carried out. Experimental results show that using ash removal additive under certain conditions can reduce gray precipitation on the surface of aluminum products, but it cannot completely eradicate it. This shows that although ash removal additive can improve the surface quality of aluminum products to a certain extent, other factors still need to be considered comprehensively.

Looking for ultimate solutions: technological innovation is key

Faced with the problem of gray precipitation in aluminum products, ash removing additive may be only part of the solution. To completely solve this problem, more in-depth research and technological innovation may be required. By improving materials and manufacturing processes and improving product quality and stability, we may be able to find a final solution and bring greater improvements to the production and application of aluminum products.