Is electrolytic colorant suitable for large-scale industrial production?

2024-04-25 15:30

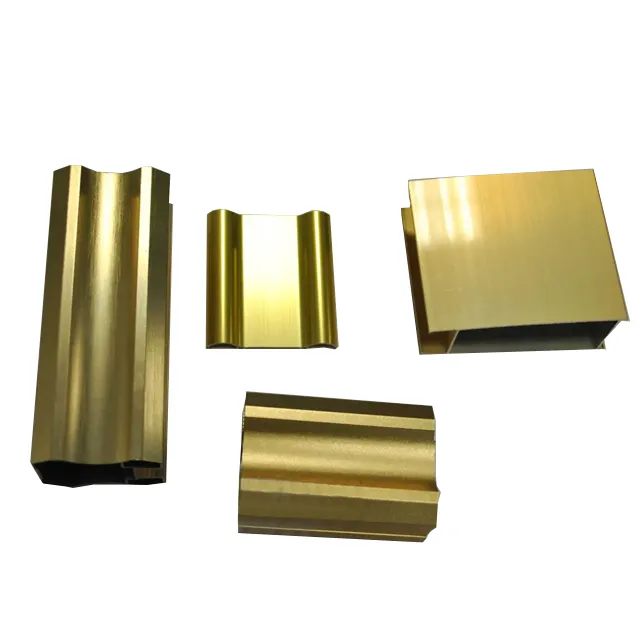

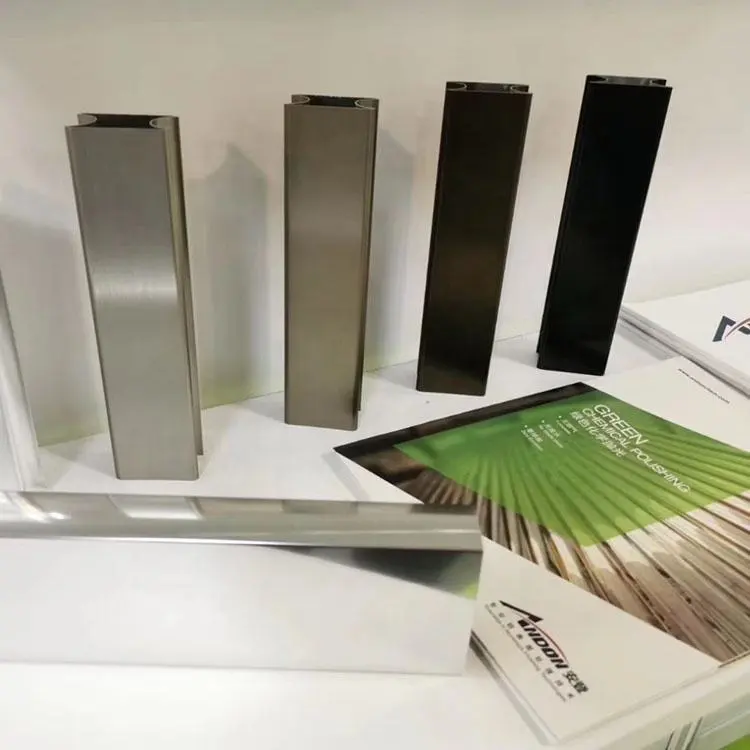

Electrolytic coloring is a common surface treatment method that improves the appearance and performance of products by forming a colorful oxide film on the metal surface. As an important part of this process, electrolytic coloring agent has attracted much attention for its applicability in large-scale industrial production. This article will delve into the applicability of electrolytic colorant in large-scale industrial production and answer common questions from consumers and industry.

1. Stability of additives: a key factor affecting large-scale production

In large-scale industrial production, the stability of additives is one of the key factors affecting their applicability. The stability of additives directly affects the stability of the production process and the quality stability of the product. Therefore, it is necessary to select electrolytic colorants with high stability and controllable quality according to different production scales and process requirements to ensure the continuity and stability of production.

2. Cost control: an important consideration related to the economic benefits of the enterprise

In large-scale industrial production, cost control is one of the important considerations in business operations. The price, dosage and cost-effectiveness of additives directly affect production costs and product prices. Therefore, choosing electrolytic coloring additives with reasonable prices, moderate dosage, and stable performance is crucial to the economic benefits of the enterprise. At the same time, the effect and durability of additives need to be comprehensively considered to ensure product quality and market competitiveness.

3. Production efficiency: a key indicator to enhance corporate competitiveness

In large-scale industrial production, production efficiency is one of the important indicators of enterprise competitiveness. The selection and use of additives directly affects the efficiency and production cycle of the production process. Therefore, it is necessary to choose Electrolytic coloring additives with good dispersion and stability to improve production efficiency, reduce production costs, and enhance the market competitiveness of enterprises.

4. Environmental protection requirements: in line with important trends in industry development

With the improvement of social environmental awareness and the strengthening of environmental protection requirements, the applicability of electrolytic coloring agents in large-scale industrial production has also attracted attention. The environmental protection and safety of additives are one of the important considerations for companies to choose. Therefore, it is necessary to choose an electrolytic colorant that meets environmental protection requirements, is non-toxic and harmless, to protect the environment, ensure the health of employees, and promote the sustainable development of the industry.

5. Technical support and services: ensure the smooth progress of production

In large-scale industrial production, technical support and services are important guarantees to ensure smooth production. Choosing an Electrolytic coloring agent supplier with a professional technical team and complete after-sales service can promptly solve problems encountered in production, ensure the continuity and stability of the production line, and improve the company's production efficiency and product quality.

Conclusion

In summary, the applicability of Electrolytic coloring additives in large-scale industrial production is affected by many factors, including the stability of the additive, cost control, production efficiency, environmental protection requirements, and technical support and services. Only by comprehensively considering these factors and selecting the appropriate electrolytic colorant can we ensure the smooth progress of production and enhance the competitiveness and market position of the company. Therefore, when choosing Electrolytic coloring additives, companies should conduct comprehensive evaluation and research, and choose products that meet their own production needs and industry development trends to achieve dual improvements in economic and social benefits.