How to use wax remover additive?

2024-06-10 15:30

In the production and processing of aluminum products, wax removal is an essential step, and wax remover additive is an important part of it. Its use steps are crucial to ensure the cleanliness and quality of the product surface. This article will delve into the steps of using wax remover additive and reveal the secrets of this industry for you.

The steps to use wax remove additive:

1. Preparation

Before proceeding with the wax removal process, you first need to make preparations. This includes cleaning the surface of the aluminum product to remove dust and dirt from the surface to ensure the effectiveness of the wax removal treatment.

2. Choose the appropriate wax removal additive

Depending on the specific requirements of the product and what is being treated, it is crucial to select the appropriate wax remover additive. Different types of wax removal additives may have different compositions and properties, so selection needs to be based on actual conditions.

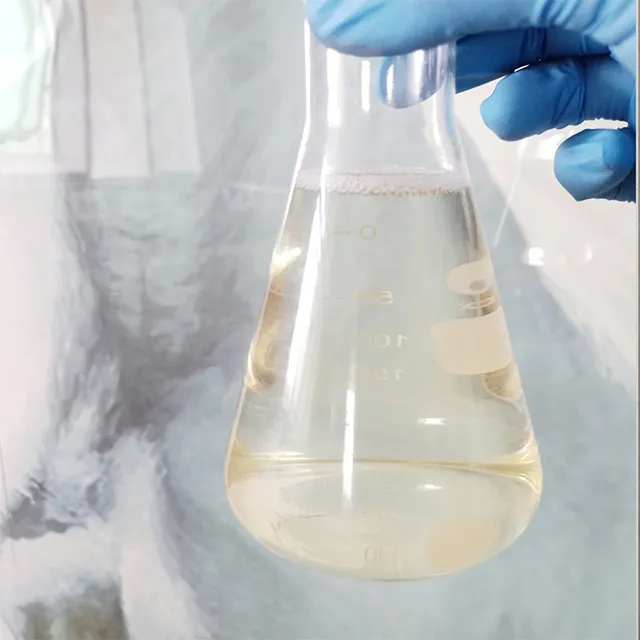

3. Dissolve additives

Dissolve the selected wax remover additive in an appropriate amount of solvent. Commonly used solvents include water, alcohol or organic solvents. Make sure the additives are fully dissolved and the solution is uniform and stable.

4. Apply wax removal solution

Apply the dissolved wax removal solution evenly on the surface of the aluminum product. You can use a brush, spray gun or dipping method to ensure that every part is covered.

5. Let stand

Let the aluminum product sit for a period of time to allow the wax removal solution to fully penetrate and act on the aluminum surface. The standing time can be adjusted according to the specific conditions of the product and the requirements of the wax removal additive, usually between a few minutes and a few hours.

6. Cleaning

After standing for a certain period of time, the aluminum products are cleaned to remove the wax removal solution and residue on the surface. When cleaning, you can use clean water or other cleaning agents to ensure that the surface is clean and free of residue.

7. Check

After the cleaning is completed, inspect the aluminum products to ensure that the effect of the wax removal treatment meets the requirements. When inspecting, you need to pay attention to whether the surface is clean, free of residue, and whether the color is uniform.

8. Follow-up processing

After the wax removal process is completed, other subsequent processes can be carried out as needed, such as anodizing, coloring, etc., to meet the final product requirements.

9. Quality Control

During the entire wax removal process, each step needs to be strictly controlled to ensure that product quality and surface treatment effects meet standard requirements. Wax removal additive and treatment processes are regularly tested and adjusted to ensure the stability and consistency of product quality.

Conclusion

The steps to use wax remover additive play a vital role in ensuring the cleanliness and quality of the surface of aluminum products. Through scientific and reasonable selection of additives and strict control of the processing process, the cleanliness and consistency of the product surface can be ensured, and the competitiveness and market share of the product can be improved.