How to judge the quality of aluminum anodizing dyes?

2024-04-02 15:30

During the anodizing process of aluminum products, choosing the right dye is critical to the final product quality and performance. However, how to judge the quality of aluminum anodizing dyes has always been the focus of attention in the industry. Today, we will delve into this issue and share some tips and experiences for judging the quality of aluminum anodizing dyes.

1. Examine the stability and durability of dyes

High-quality aluminum anodizing dyes should have good stability and durability. Stability refers to the stability of the dye during the anodization process and whether it can maintain consistent color and effect; durability refers to the light resistance, heat resistance, weather resistance and other properties of the dye in long-term use, and whether it can maintain the color and effect. The appearance is not damaged.

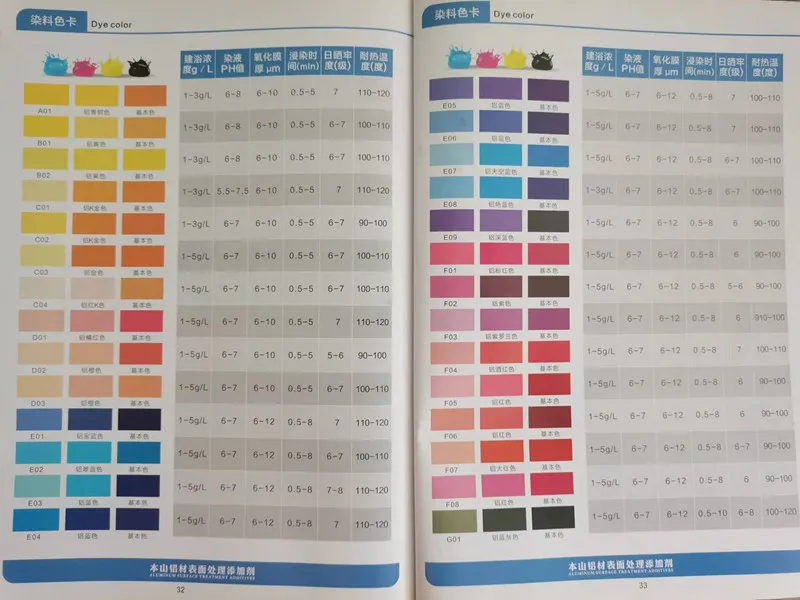

2. Check the color and effect of the dye

The color and effect of dyes directly affect the appearance and decorative effect of the product. High-quality aluminum anodizing dyes should have bright colors, full effects, and be able to meet the needs of customers and the market. When selecting dyes, you can check whether the color and effect of the dye meet the requirements through sample trial production and on-site observation.

3. Evaluate the cost and economics of dyes

The cost and economics of the dye are one of the important considerations in selection. High-quality aluminum anodizing dyes should have reasonable prices, which can reduce the production cost and market price of the product and improve the competitiveness of the product while ensuring quality. When choosing dyes, you can comprehensively consider price, quality and performance, and choose products with high cost-effectiveness.

4. Pay attention to the environmental protection and safety of dyes

Environmental protection and safety are important factors that cannot be ignored in modern production. High-quality aluminum anodizing dyes should comply with environmental standards, contain no harmful substances, and be harmless to the human body and the environment. When choosing a dye, you can check the product's safety data sheet and environmental certification to ensure the environmental protection and safety of the dye.

5. Examine the supplier’s reputation and qualifications

When choosing aluminum anodizing dyes, you also need to examine the supplier's reputation and qualifications. High-quality suppliers usually have a good reputation and rich experience, and can provide reliable quality products and professional technical support. When selecting a supplier, you can check its company qualifications, customer reviews and industry reputation, and choose a reputable supplier.

6. Field testing and verification of dye performance

Finally, to ensure dye quality and suitability, field testing and verification of dye performance can be performed. Through laboratory testing and actual production applications, the stability, durability, color effect and other aspects of the dye's performance can be evaluated to determine whether the dye meets product requirements.

7. Refer to user feedback and industry evaluations

In addition to the above methods, you can also refer to user feedback and industry evaluations to understand the actual application effects and market reputation of aluminum anodizing dyes. By communicating with experts and users in the industry, you can obtain more information about the quality and performance of dyes, which will provide a reference for selecting appropriate dyes.

Conclusion: Scientific evaluation and selection of high-quality dyes

Choosing dyes suitable for aluminum anodization requires comprehensive consideration of factors such as stability, color effect, cost economy, environmental safety, supplier reputation, and field verification. Only through scientific evaluation can aluminum anodizing dyes with reliable quality and excellent performance be selected, providing strong support for product production and market competition.