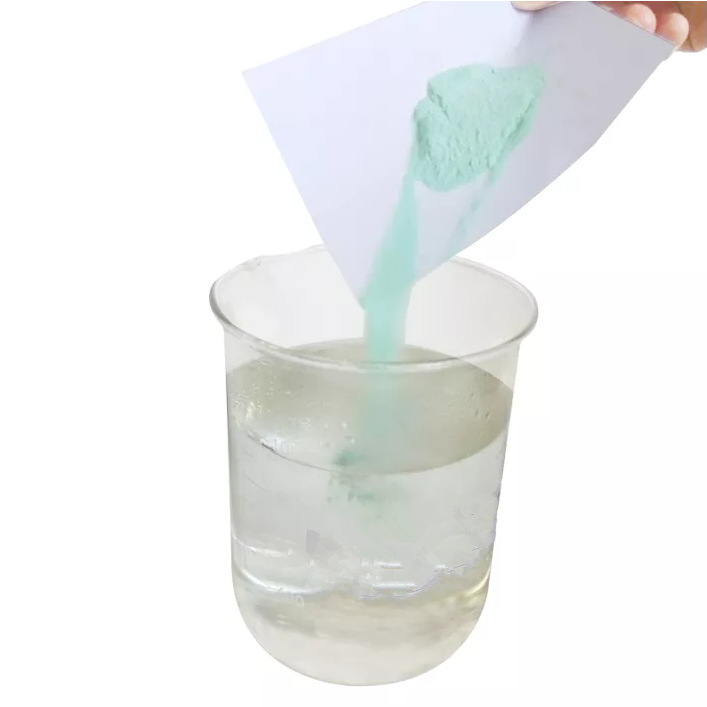

Aluminum Anodizing Sealant Powder

1, good processing: anodic aluminum oxide plate decorative strong, moderate hardness, can be easily bent into shape. 2, good weather resistance: anodic aluminum oxide plate use for a long time without discoloration, no corrosion, no oxidation, no rust.

3. Strong Metal Sense: the surface hardness of the anodized aluminum sheet is high, up to gem grade, good scraping resistance, no paint covering on the surface, keeping the metal color of the aluminum sheet, highlighting the modern metal sense, and improving the product grade.

Aluminum Anodizing Sealant Powder

|  |

Working condition

| Concentration | 5g/l |

| PH | 5.3-5.8 |

| Temperature | 75-95℃ |

| Time | 1-10min |

| Water quality | Pure water |

light resistance:good

color fastness to heat:good

Packing

Function and feature:The product is used in the process of anodizing aluminum alloy. It is composed of nickel metal salt, complexing agent, ash suppressant, buffer agent, dispersant, surfactant, etc.

It is especially suitable for high quality anodizing process of aluminum alloy. Non-fading. Can provide aluminum surface hardness. High thermal and light resistance.

Low consumption and easy to control.

Storage condition:The dye should be sealed up and stored in a dry place.

Certification