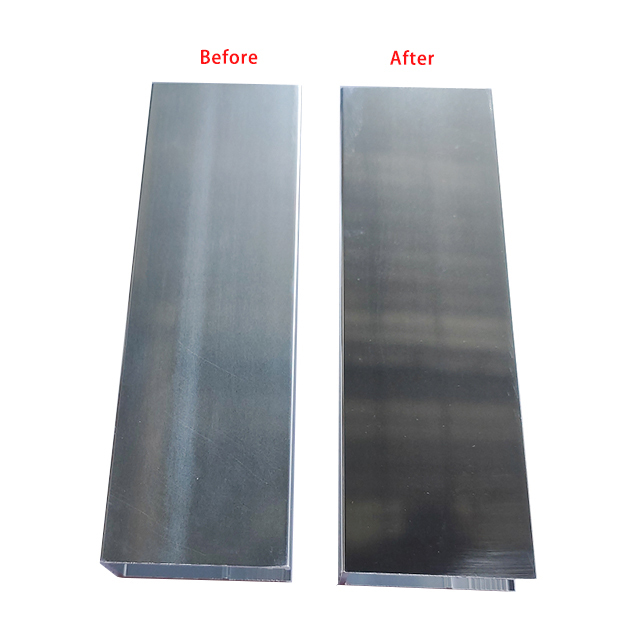

Two acid polishing additive

NEW Polingshing additive,is a kind of clear acid liquid with powerful degreasing surface active agent,emulsifier and functional agent.This product can eficiently remove grease and natural oxide film on aluminum profiles surface and results no harm to alumium profiles.

Used for pre-treatment of aluminum profiles power coating and anodization.It has advantages of low cost,little aluminum consumption,brightening and energy-saving comparing to alkaline etching treatment.

Two acid polishing additive

Product features:

1. No nitric acid, no yellow smoke.

2. One successful polishing, fast light and high efficiency.

3. No nitric acid, good stability, simple operation, can reduce the operator load, reduce safety risks.

4. Less corrosive to aluminum, less aging of tank liquid and less product consumption. Reduce manpower and sewage treatment costs.

5. Simple management and control. The newly prepared liquid only needs to control the aluminum ion content and temperature, and the temperature and time during polishing operation. Strictly control the ratio of phosphoric acid to sulfuric acid.

6. After the profile is polished, it can drip dry for a long time without the appearance of flow mark, which can reduce the amount of liquid medicine taken out and reduce the cost.

Process flow :

Bath Preparation:

| Name | Quantity | Unit |

| phosphoric acid (H3PO4) | 60 | % |

| Sulfuric acid (H2SO4) | 40 | % |

| BS-H05 | add 4-6 of the total amount of H2SO4 and H3PO4 | % |

| Temperature | 90-100 | ℃ |

| Specific gravity | >1.85 | |

| Aluminum ion | 30-40 | g/L |

Tank liquid maintenance

1. Replenishment of tank liquid: The replenishment liquid must be finished in advance and can be added to the tank two hours later. A spare tank of a certain volume can be prepared and prepared in advance according to the slotting ratio. When the liquid level of the working tank drops, the mixed agent of the spare tank can be directly added to the working tank, Stir well and serve.

2. When adding recovery tank liquid, add 70% recovery liquid and 30% new acid.

3. When the aluminum ion content is close to 40g/L, the normal proportion tank can be supplemented to reduce the aluminum ion concentration.

4. If the tank liquid is left open for too long, it will not shine because of too much water absorption. It needs to be heated to about 110℃ to evaporate the water or use waste aluminum to do repeated polishing to remove the water before resuming production.

Packing:25kgs/drum

Certification