Copper coloring additives

1. The color is bright and complete.

2. The tank fluid is stable and easy to operate.

3, light and heat resistance, adhere to the gloss. GY-RS series of aluminum dyes have strong ability of anti-ultraviolet and anti-thermal differentiation, aluminum profiles to ensure that the dyed aluminum can accept long-term sunlight does not fade. Different from the mask spraying, this series of aluminum dyeing agent is adopted filling dyeing, by the dyeing agent of aluminum can retain metallic luster.

4. The cost is moderate and the mall is broad. The cost of dyeing aluminum finished products and electrolytic coloring aluminum finished products is appropriate, because the dyeing system is rich, greatly widening the market of aluminum finished products, improving the level of electrophoresis profiles, and enhancing the market competitiveness of sealing profiles, satisfied with household appliances production, industrial materials, decoration and other needs.

Copper coloring additives

BS-Z01 Copper coloring additives are a solid powder for coloring to aluminum profile after anodizing with advantages of good solution stabilization, good homogenization and reproducibility. It is stable and easily soluble in water. It should be stored in a cool dark place.

Storage condition:The dye should be sealed up and stored in a dry place.

Bath Preparation:

| Name | Quantity | Unit |

| BS-Z01 | 20 | g/L |

| Sulphuric acid (H SO) | 18 | g/L |

| stannous sulfate (SnSo) | 8-15 | g/L |

| Running Water | Balance |

Process Parameter:

| Name | Quantity | Unit |

| Voltage | 16-20 | V |

| Temperature | 18-21 | ℃ |

| PH | 0.8-1.0 | |

| Time | depends on the color shade |

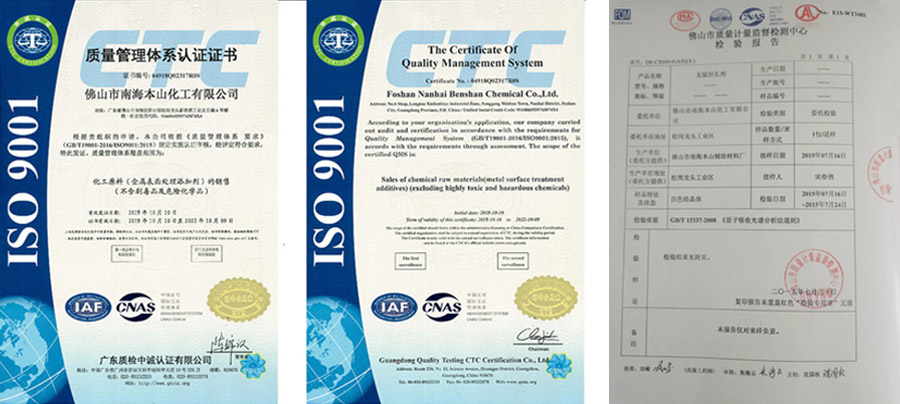

Certification

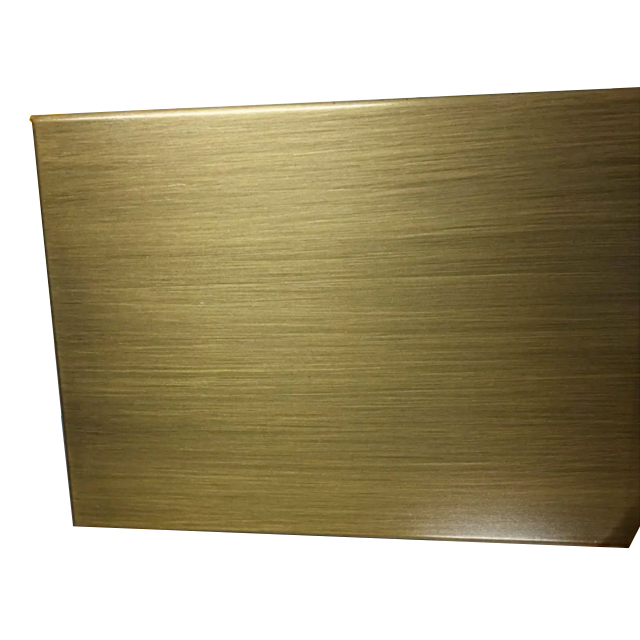

Dye color

Packing:25kg plastic bag packing; Protect from heating,