Aluminium Nickel Free Anodizing Sealant

(1) corrosion resistance. Aluminum anodic oxide film can effectively protect aluminum substrate from corrosion, anodic oxide film is obviously better than the natural oxide film, film thickness and sealing quality directly affect its corrosion resistance.

(2) hardness and wear resistance. The hardness of anodic oxidation of aluminum is much higher than that of Aluminum Matrix. The hardness of Aluminum Matrix is HV100. The hardness of common anodic oxidation film produced by aluminum profile manufacturers is about HV300, and the hardness of hard oxide film can reach HV500 or above. The relationship between wear resistance and hardness is consistent.

Aluminium Nickel Free Anodizing Sealant

Function:The product is used in the process of anodizing aluminum alloy.

It is composed of nickel metal salt, complexing agent, ash suppressant, buffer agent, dispersant, surfactant, etc.

It is especially suitable for dyed aluminum alloys. Non-fading. Can provide aluminum surface hardness. High thermal and light resistance. Low consumption and easy to control.

Storage condition:The dye should be sealed up and stored in a dry place.

Working condition

| Concentration | 5-7g/l |

| PH | 5.5-6.5 |

| Temperature | 50-70℃ |

| Time | 6-15min |

| Water quality | Pure water |

Packing

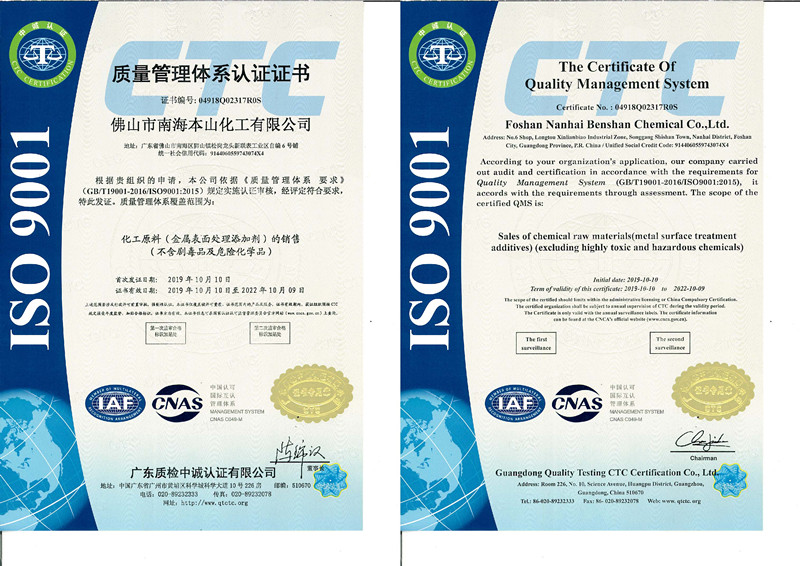

Certification

1. Strong buffer capacity, strong resistance to interference from impurity ions, strong anti-pollution ability;

2. Easy to control the components of the bath, wide process parameters, due to the process fluctuations, process parameters of the previous process caused by changes in the sealing effect of small impact, nickel-fluorine consumption balance, pH stability, good sealing effect, can minimize the precipitation of Dyes,

3,.the composition of exquisite, select the right Surfactant, avoid the sealing of common fly ash and other ills, the ability to suppress ash;

4. After sealing, the surface gloss and hardness of the profile are improved, and the color fastness and weatherability of the film are improved, which can deal with the sealing effect of high quality.