Will acid etching additive affect workers' health during production?

2024-05-03 15:30

Acid etching additive plays an important role in metal processing and surface treatment processes. However, with the increasing awareness of environmental protection and workers' health, the impact of acid etching additive on workers' health during the production process has also attracted widespread attention. This article will explore the potential impact of acid etching additive on workers' health and provide corresponding protective measures to ensure the safety and health of workers during the production process.

1. Characteristics of acid corrosion additive

Acid corrosion additives are typically solutions of acidic chemicals that quickly remove oxides and impurities from metal surfaces. These additives play a key role in the production process, but their chemical properties pose potential risks to worker health, such as skin, eye and respiratory irritation.

2. Risk of direct contact

During the production process, workers may come into direct contact with acid etching additive, including skin and eye contact. This can cause skin burns, allergic reactions, and eye irritation. To protect against these risks, workers should wear appropriate protective equipment such as acid-resistant gloves, goggles and protective clothing.

3. Inhalation of harmful gases

The acid etching additive may release harmful gases during the treatment process, such as hydrofluoric acid, hydrochloric acid, etc. These gases are potentially harmful to workers' respiratory systems and may cause symptoms such as coughing and wheezing. To reduce risks, the production environment should be well ventilated and workers should be provided with respiratory protective equipment such as masks.

4. Effects of long-term exposure

Long-term exposure of workers to acid etching additives may lead to chronic health problems, such as skin allergies, respiratory diseases, etc. Therefore, companies should regularly monitor the health status of workers and provide workers with regular health examinations to detect potential problems early.

5. Importance of safe operating procedures

To ensure worker health, companies should develop strict safety operating procedures, including the storage, transportation, use and waste disposal of additives. Workers should receive professional training to understand the use and safety measures of acid corrosion additive to ensure safe operations during the production process.

6. Precautions for waste liquid disposal

The acid etching additive produces waste liquids during the production process, which may pose potential threats to the environment and worker health. Therefore, enterprises should take appropriate waste liquid treatment measures to ensure the safe discharge or recycling of waste liquid and reduce the risk of secondary exposure to workers.

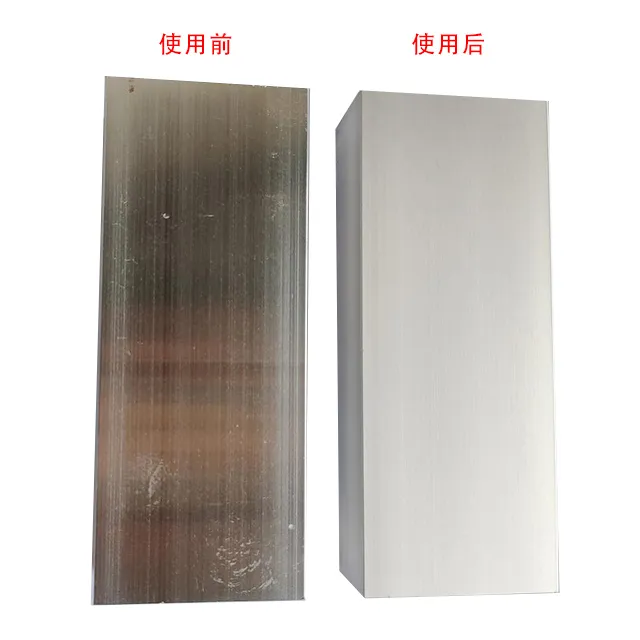

7. Exploration of new environmentally friendly additives

With the development of science and technology, more and more companies are beginning to explore new environmentally friendly acid etching additives. These additives maintain a good surface finish while reducing the impact on worker health. Companies can consider introducing these new additives to reduce health risks during production.

8. Industry standards and supervision

Industry standards and regulations have put forward clear requirements for the use and safety protection of acid corrosion additives. Enterprises should strictly abide by relevant standards and regulations to ensure the safe use of additives and protect the health and safety of workers.

Acid etching additive has potential risks to workers' health during the production process, but by taking appropriate protective measures and strict safety operating procedures, these risks can be effectively controlled. Enterprises should continue to explore new environmentally friendly additives and ensure that workers receive professional training and health examinations to provide workers with a safe and healthy working environment. Through comprehensive measures, companies can achieve the coexistence of efficient production and protection of worker health.